vicutcnc@cncvicut.com

vicutcnc@cncvicut.com

+86 551 6577 4134

+86 551 6577 4134

Get A Quote

Get A Quote

vicutcnc@cncvicut.com

vicutcnc@cncvicut.com

+86 551 6577 4134

+86 551 6577 4134

Get A Quote

Get A Quote

Roll-to-Roll & Roll-to-Sheet Label Cutter!

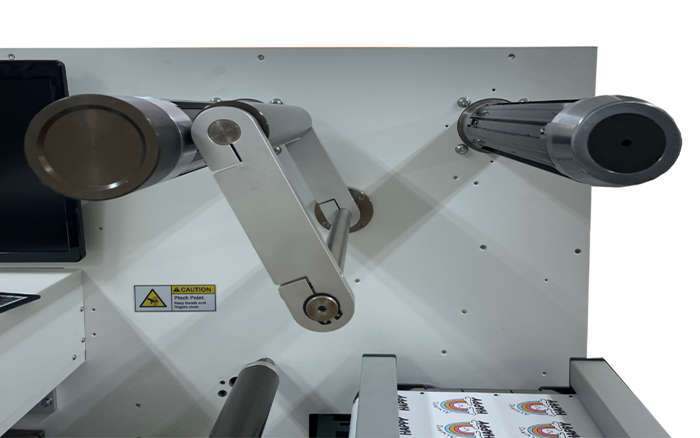

The VICUT digital label cutter VR3350D is most advanced roll-to-roll and roll-to-sheet digital blade finishing system! The label finisher allows customers to digitally die-cut label stock and convert it either roll to roll, or roll to sheet with an inline sheeting unit.

The high speed cutting head is designed to run at speeds up to 9m/min, and it can be equipped with up to 12 cutting heads at once!

The rotary label cutter VR3350D is perfect for short to medium length print finishing, and even more enticing is the ability to automatically sheet to size without any additional equipment. You can use the sheeting system inline with cutting, or as an offline solution to cut roll products to any length needed!

KEY FEATURES

Fast and high precison with full-servo motor

Fully automatic tension and feeding control

Intelligent position,choose file automatically.

Standard 4 cutting heads,distance can be adjusted automatically

Support 3 units cutting simultaneously

Intelligent cutting with trajectory optimization

Technical Parameters

| Model Name | Digital Label Die Cutter VR3350D |

| Maxi. roll diameter | 450mm |

| Cutting media width | 150--350mm |

| Max. label size | 330x600mm |

| Mini. label length | 10mm |

| Max. die cutting speed | 9m per minute (depends on label shape and size) |

| No. of die cutting heads | 4pcs heads(standard), max. up to 6pcs heads |

| Die cutting blades | Tungsten steel blades |

| Die cutting precision | 0.1mm (duplicate) |

| Code scanner | CCD camera |

| Slitting width | 10 ~ 330mm |

| Slitting blades | 4pcs(standard ), up to 15pcs |

| Slitting speed | 100m/min |

| Slitting precision | 0.1mm |

| Data transfer method | PC direct |

| Working voltage | 110-127VAC,50-60HZ,1000Watts 220-240VAC,50-60HZ,1000Watts |

| Machine dimension | 205cm(L) x 126cm(W) x 165cm(H) |

| Weight(N.W/G.W) | 1200kg |

| Packing size | 2210*1380*1910mm |

| Optional function | cutting head |

| sheet paper cutter | |

| slitting unit | |

| upper rewinder | |

| laminating linear system |

Details Description

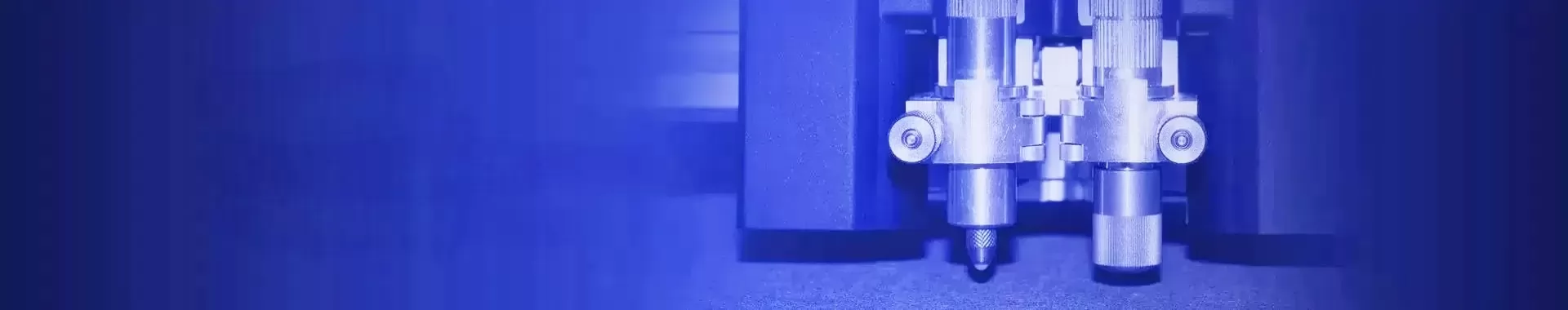

Multiple die cutting heads

The VR3350D digital label die cutter utilizes a high-precision screw transmission system. Its maximum speed can reach 9 meters per minute. It features individual control for the 4 heads, combined with the function of automatic adjustment of the heads' distance, which can be automatically closed or opened according to the number of labels.

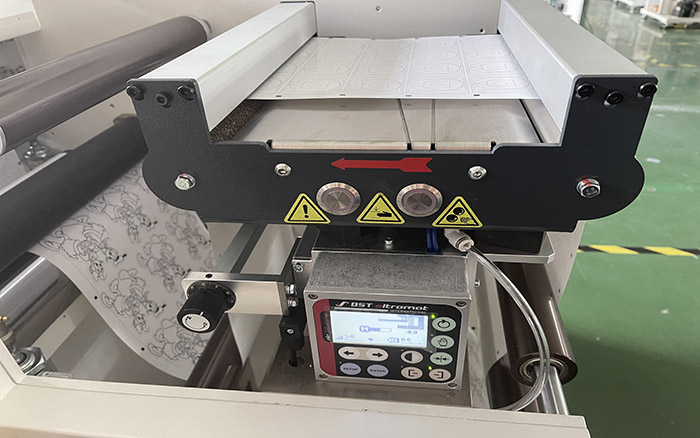

CCD Camera Identification System

The CCD camera positioning and identification system can recognize the sequence codes of each job, enabling smooth automatic job exchange during feeding and cutting.

High precision feeding system

It utilizes a high-precision ultrasonic web-guide system, ensuring accurate paper feeding in preparation for the next die-cutting step.

Cold lamination

Automatic lamination before die-cutting makes the finished labels more durable and suitable for a wider range of applications. The lamination linear system is optional.

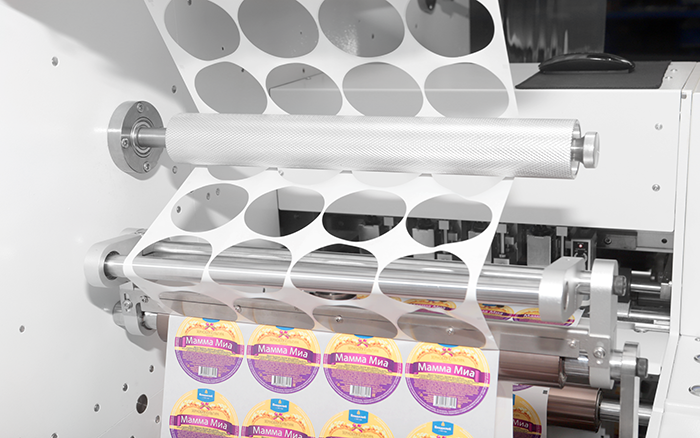

Automatic waste removal system

With the automatic tension control of the waste discharge system, the label cutting waste will be automatically removed and separated from the winding, so as to obtain a clean label roll for the next process.

Slitting system

Utilize round blades, automatically cut the label paper into small rolls as needed,up to 15pcs blades can be used. Maximum slitting speed can reach to 100m/min.

Down rewinder

Default main rewinder for roll to roll process.

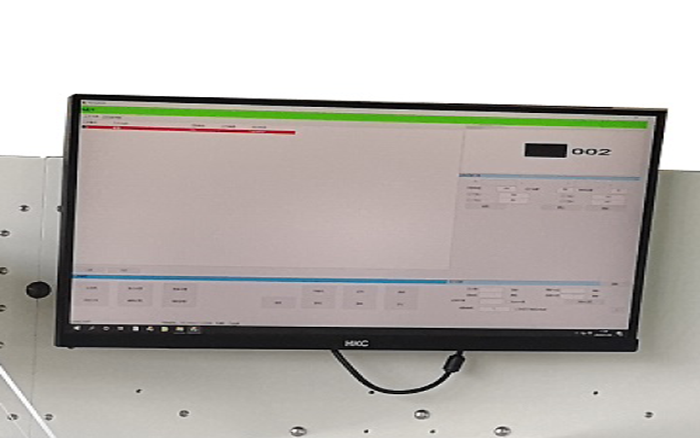

Easy-to-use dedicated software

• Running status can be seen in a real-time.

• Support file database.

• Choose the quantity of the heads based on graphics.

• Intelligent cutting with trajectory optimization.

• Adjust heads distance automatically.

• Auto-generate the working records.

Upper rewinder. (Optional)

Optional upper rewinder to separate labels in every second row after slitting.

Inline roll to sheet cutting system.(optional)

The optional built-in sheet cutting module can be in-lined with the main die-cutting to perform the roll to sheet cutting process.

Laminating Linear System

An additional roller for removing the backing paper of the laminating film allows users to use high-end laminating films, which makes the final labels durable and up-market.

Tools & Accessories

Die Cutting Blades

Special 45 degree 10U die cutting blade, suitable for cutting 0.25 mm thick adhesive label materials such as sticker, coated paper, synthetic paper, PP, PET, etc.

Die Cutting Blades Holder

Precision blade holder, built-in bearing design, cooperate with machine blade compensation function, make cutting more smooth. Easy to install the blade and adjust the distance between the blade tips.

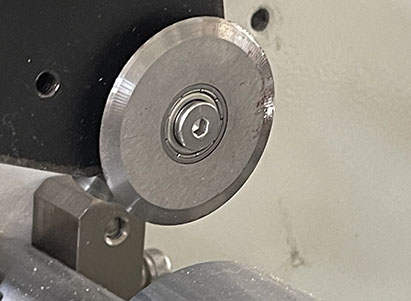

Slitting Blades

Tungsten steel ring blades, high cutting precision to divide big rolls into smaller one.

Application

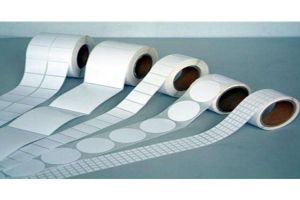

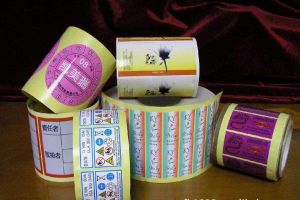

Applicable Industry: VR3350D roll to roll label finisher is mainly used in producing wide range of labels including blank labels, ink labels, chemical labels, beverage labels, bottled water labels, chili source labels, coffee labels, cosmetic labels, home appliance label, toiletries label, gum label,wine labels and more.

Applicable Materials: Stickers, Paper, PP, BOPP, PET, PVC & More!

Company Service: As a professional roll die cutter supplier dealer, Vicut believes that excellent service always gains loyal clients. We provide 24/7 online support, with all-round technical assistance and solutions offered within 8 hours. Additionally, we offer remote training, user-friendly manuals, and operation videos.

Roll Sticker Cutter Working Samples:

|  |  |  |

|  |  |  |

|  |  |  |

Packing photos