vicutcnc@cncvicut.com

vicutcnc@cncvicut.com

+86 551 6577 4134

+86 551 6577 4134

Get A Quote

Get A Quote

vicutcnc@cncvicut.com

vicutcnc@cncvicut.com

+86 551 6577 4134

+86 551 6577 4134

Get A Quote

Get A Quote

VR240X digital label finisher is redeveloped based on the original desktop digital label die-cutting machine VR240. There are big differences both in software and function.VR240X digital label die cutter has the function of automatic order change which can meet the needs of customers with small batches and many samples. The cutting distance auto adjustment function is convenient for the user to operate and solves the customer's die-cutting work with one button.

KEY FEATURES

AUTOMATIC DUAL HEAD GAP CONTROL

CONSTANT PRESSURE CONTROL

AUTOMATIC MATRIX REMOVAL

UP TO 8PCS SLITTING KNIVES

SUPPORT MAX.ROLL WIDTH 240MM

MAX.DIE CUTTING SPEED 8M/MIN

ABLE TO WORK SYNCHRONIZED ONLINE WITH DESK TOP LABEL PRINTER

CCD CAMERA.RETRIEVAL THE CODES ON THE PRINTERD MEDIA AUTOMATICALLY

JOB EXCHANGE FUNCTION.VERY CONVENIENT FOR DIFFERENT LABEL JOBS ON THE ROLL MEDIA

INLINE COLD LAMINATION

CUT MAX.330MICORN THICKNESS

Technical Parameters

Model Name | Digital Label Die Cutting Machine VR240X |

Cutting Technology | Advanced digital die cutting with blades |

Cut mode | Roll to roll fly |

Maxi. roll diameter | 290mm |

Max. die cutting speed | 8m/minute(cut 7cmx15cmsquare) |

Die cutting precision | 0.1mm(repeat) |

Cutting media width | 80--240mm |

Max. label width | 230mm |

Max. label length | 300mm |

Cut track | CCD Camera/Blank |

Min.distance from mark to edge | 2mm |

Min.distance between jobs | 2mm |

No. of cutting heads | 2sets |

Laminating Width | 225mm |

Film roll diameter | 230mm |

Max.waste roll diameter | 300mm |

Slitting speed | same with cutting speed |

Slitting width | 10-230mm |

Slitting precision | 0.1mm |

No. of slitting blades | 4sets(up to 8 sets) |

No. of rewinder | 1 set (3’’) |

Machine dimension | 91*63*74cm(L*W*H) |

Machine weight(N.W/G.W) | 150kg/233kg |

Working voltage | AC100-240V, 50-60HZ, 1000WATTS |

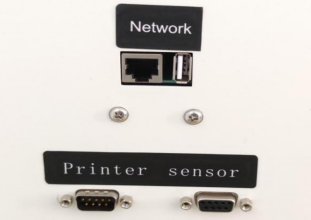

Data transfer method | USB2.0/Ethernet 10/100Base-T/GPIO |

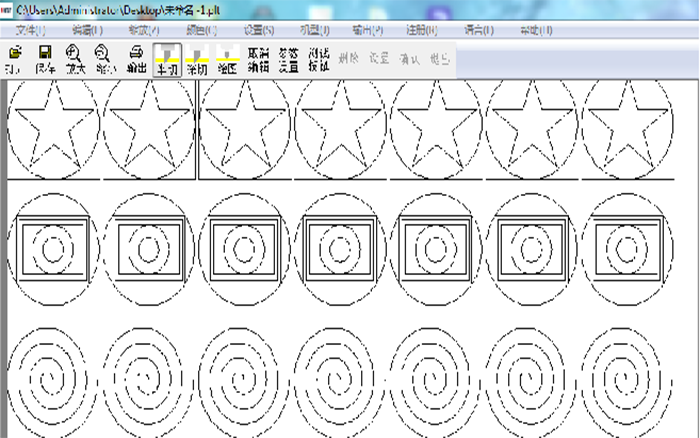

Software | VICUT minicut |

File format | PLT, PDF,DXF |

Die cutting blades | Tungsten steel blades |

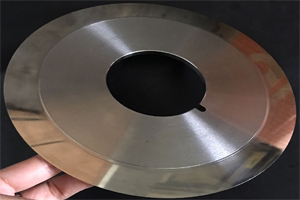

Slitting blades | Rotary round blades |

Marking sensing method | Single mark or double mark |

Other function and device | Auto adjust head distance |

Auto change cut job | |

Auto set knife drop point | |

Waste removal | |

Optional | Connect printer device |

Flat base |

Optional Functions | ||

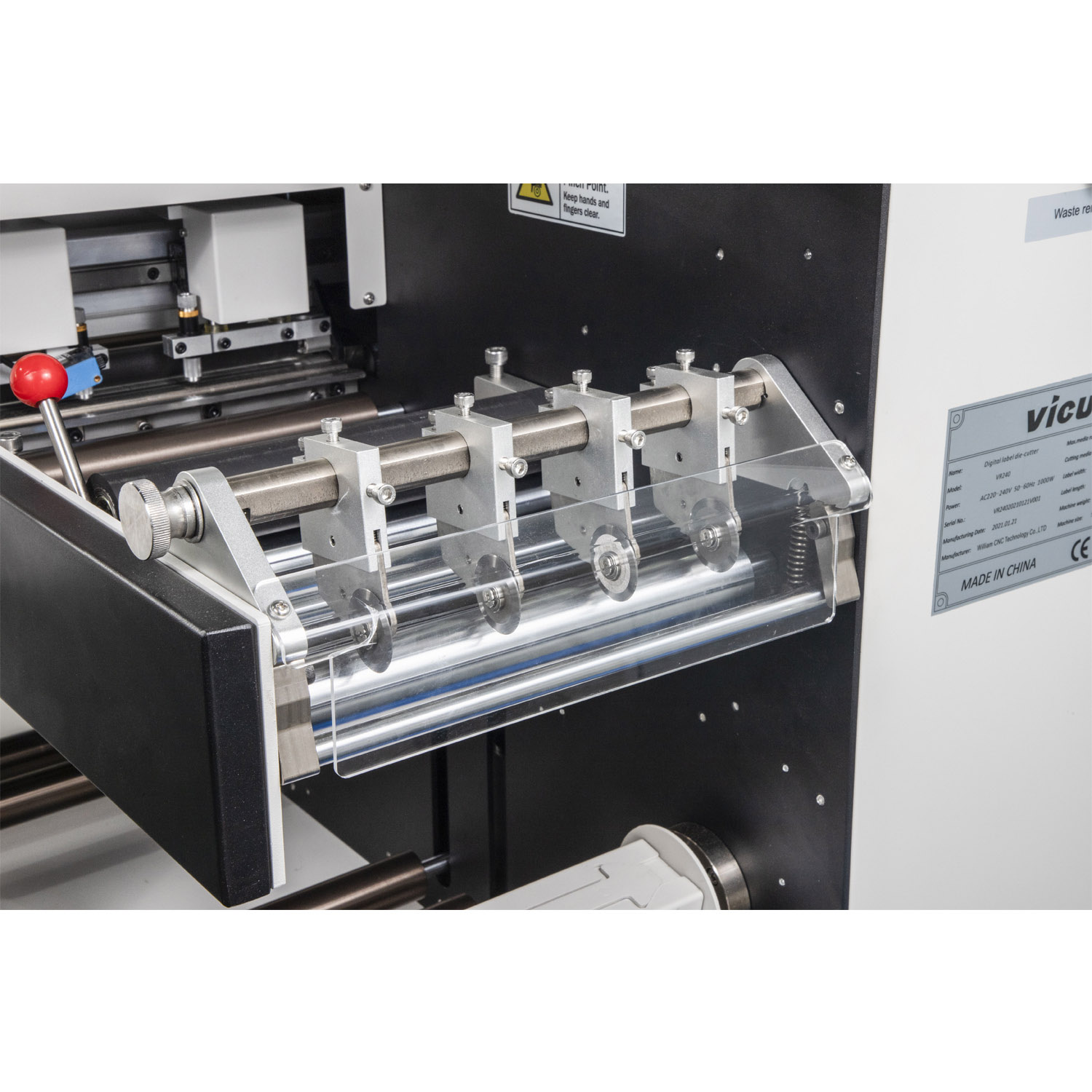

1 |  | Slitting unit. The standard slitting units for VR240X digital label cutter is 4pcs, user can choose the quantity of slitting blades as required, up to 8pcs. The slitting functions can be used alone, as slitting-only-mode. |

2 |

|

Online print components. Through this function, VR240X can be connected with the printer to realize inline work and speed synchronization. It can run with small roll label printers like Memjet VP series or OKI Pro series, ANY-002, EPSON, PRIMERA, UNINET, etc.

|

3 | | Roll to Sheet Cutter RS350. It is suitable for transverse cutting of various roll materials. Suitable materials: Self-adhesive, PP synthetic, aluminum plastic film, PET, PVC, white card, copper plate and other paper and flexible materials. Technical Parameters: Cutting media width: 100-350mm Maxi label width: 350mm Mini label length: 10mm Maxi label length: 500mm Highest paper cutting speed: 150/Minute Cutting tracking: single mark or double mark Cutting accuracy: 0.1mm Size (W*D*H) : 670*460*915mm Weight: 180kg Power supply: 220-240VAC 50-60HZ, 500W |

Details Description

Dual cutting heads

VR240X equipped with a dual cutting head system, the gap between heads is adjusted automatically via control system, not manually, greatly improve the cutting efficiency.

CCD Camera Digital cutting positioning system

The CCD Camera positioning system scans the marked points printed on the material to obtain the cutting dies information with fast speed and feed it back to the machine control system, so as to realize the digital cutting.

User friendly touch screen panel

Large size touch screen operation panel, professional UI interface design, in line with user habits, operation is more convenient.

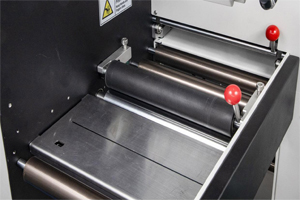

Cold lamination

Automatic lamination before die cutting, makes finishing labels more durable and more widely application.

Automatic waste removal and tension system

Under the tension of the waste discharge system, the label cutting waste paper will be automatically removed and separated from the winding, so as to obtain a clean label roll for the next process.

Slitting system

Utilize rotary round blades, automatically cut the label paper into small rolls as needed,up to 8pcs blades can be used. Maximum slitting speed can reach to 60m/min.

Platform for splicing materials

When you finish cutting a roll of label and prepare to cut another roll, you can use this platform to splice a new roll of material onto the one being processed, so as to realize smooth transition, save paper installation time and improve work efficiency.

U-disk function

VR240X roll label cutter supports network and U disk for die cutting files transmission.

Multiple interface

Network interface for transfer cutting file from PC to machine, USB interface for connecting CCD camera. Printer sensor for connecting printing assembling device.

Power socket

Plug and play, long-lasting and durable.

Easy-to-use software

Dedicated software support PLT & DXF format file, it can choose the knife down point according to shapes, the unique trajectory optimization is for perfect cutting.

Tools & Accessories

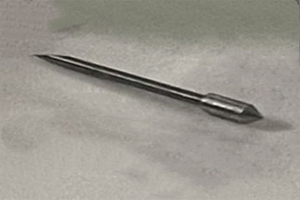

Blade holder

Precision blade holder, built-in bearing design, cooperate with machine blade compensation function, make cutting more smooth. Easy to install the blade and adjust the distance between the blade tips.

Die cutting blades

Special 45 degree die cutting blade, suitable for cutting 0.25 mm thick adhesive label materials such as sticker, coated paper, synthetic paper, PP, PET, etc.

Slitting blades

Tungsten steel rotary round blades, stable slitting the paper roll into small rolls for further processing.

Application

Applicable Industry: VR240X roll to roll digital die cutter is mainly used for small volume on-demand label production including blank labels, ink labels, chemical labels, beverage labels, bottled water labels, chili source labels, coffee labels, cosmetic labels, home appliance label, toiletries label, gum label, wine labels and more.

Applicable Materials: Stickers, Paper, PP, BOPP, PET, PVC & More!

Company Service: As a professional digital label finisher supplier, Vicut believe good service always get loyal clients, 24/7 online service, all-round technical support & solutions offered within 8 hours. Remote training, available user manual and operation video are provided.

Working Samples:

|  |  | |

|  |

Packing photos

|  |  |