vicutcnc@cncvicut.com

vicutcnc@cncvicut.com

+86 551 6577 4134

+86 551 6577 4134

Get A Quote

Get A Quote

vicutcnc@cncvicut.com

vicutcnc@cncvicut.com

+86 551 6577 4134

+86 551 6577 4134

Get A Quote

Get A Quote

The VICUT VR320 roll to roll labels cutting machine is the most affordable digital finishing system for medium volume label production. The rotary die cutting machine is a collection of laminating, die-cutting, slitting and rewinding, best solution for all-in-one label finishing. No cutting dies required, fast and precise digital cutting, fully satisfy on-demand label finishing. The label cutting machine can cut long label, and the maximum cutting length of label can reach 1.2m.

KEY FEATURES

Combination of flatbed and roll to roll mode

Segmental cutting for long labels

Real time independent cutting pressure control

One-click repeat cutting function

Automatic correction system to ensure accurate paper feeding

Cold lamination for extended label durability

Automatic matrix removal, slitting and separate rewinding

Quality components ensure machine stability

Unique trajectory optimization function ensures high precision cutting

Technical Parameters

| Model Name | Digital Label Die Cutter VR320 |

| Maxi. roll diameter | 450mm |

| Cutting media width | 40--340mm |

| Max. label width | 330mm |

| Max. label length | 400mm (segmentation cut reach to 1200mm) |

| Mini. label length | 10mm |

| Min. distance between labels | 2mm |

| Min.distance from mark to edge | 2mm |

| Min.distance between jobs | 2mm |

| Max. die cutting speed | 6m per minute (cut 7x15cm square) |

| No. of die cutting heads | 4pcs(standard ) |

| Die cutting blades | Tungsten steel blades |

| Die cutting precision | 0.1mm (duplicate) |

| Die cutting mark track mode | Non-mark, Single mark,double mark |

| Slitting width | 10 ~ 310mm |

| Slitting blades | 4pcs(standard ), up to 15pcs |

| Slitting speed | 100m/min |

| Slitting precision | 0.1mm |

| Data transfer method | USB2.0/Ethernet 10/100Base-T/GPIO |

| Working voltage | 110-240VAC 50/60HZ, 1000WATTS |

| Machine dimension | 160*100*136cm(L*W*H) |

| Weight(N.W/G.W) | Machine: 530kgs/640kgVacuum pump: 14kgs/16kg |

| Packing size | Machine: 1700*1150*1570mmVacuum pump: 450*450*500mm |

| Optional function | Multiple die cutting heads |

| Multiple slitting units | |

| Film base paper removing device | |

| Roll to sheet cutter RS350 |

Details Description

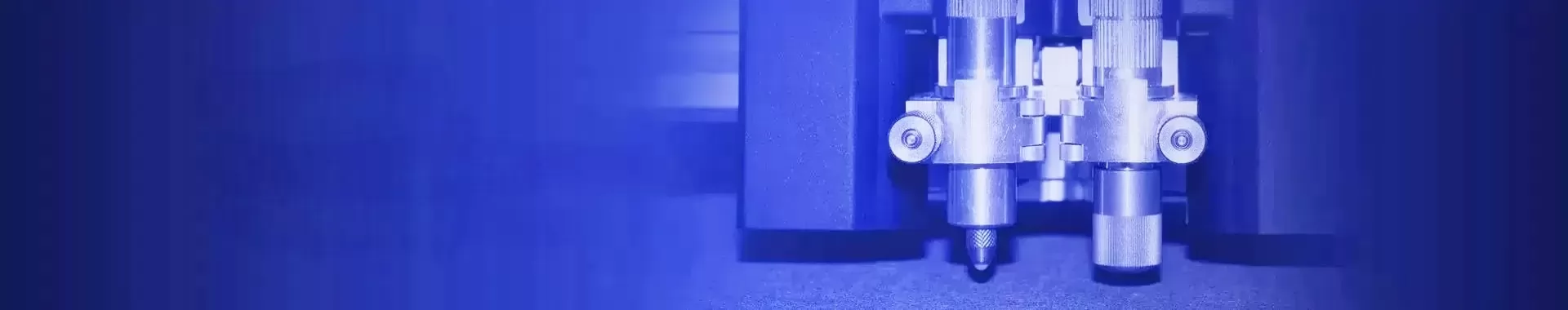

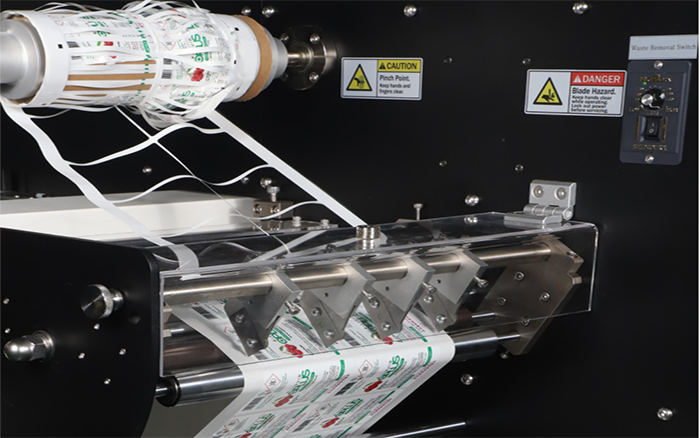

Multiple die cutting heads

VR320 works with multiple die cutting heads, up to 4 heads work at the same time, highly increase working efficiency.

User friendly operation panel

The main operation buttons are integrated into the same panel for easy operation. Touch screen interface, sensitive response, easy to set machine parameters.

Digital cutting positioning sensor

The positioning sensor scans the marked points printed on the material to obtain the cutting dies information and feed it back to the machine control system, so as to realize the digital cutting.

Automatic deviation correction system

There are two optical sensors on both sides of roll holder, automatically adjust the paper offset to ensure the accurate feeding, lay a good foundation for further processing.

Feeding detection system

After automatic deviation correction, there is an optical sensor to detect the material before feeding into the working table, make sure the paper feeding in correct way, ready for next die cutting step.

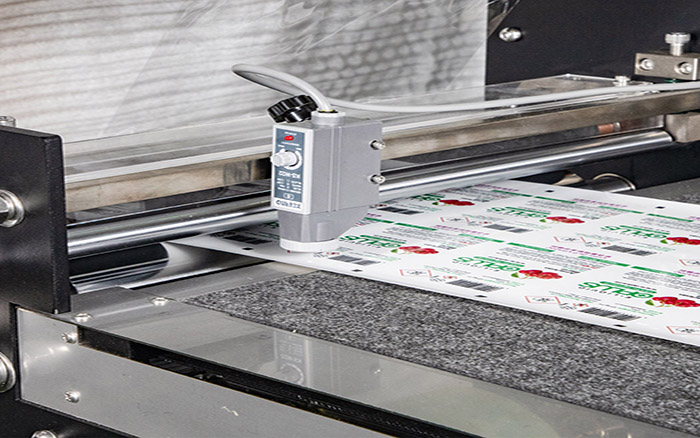

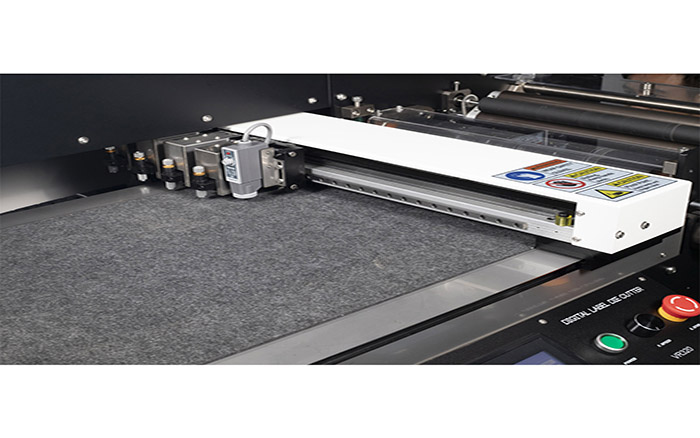

Vacuum suction cutting table

Vacuum inhaling cutting platform, the adsorption function starts along with die cutting, and automatically loosening valves after cutting finishes, to ensure cutting accuracy and smooth paper feeding.

Platform for splicing materials

When you finish cutting a roll of label and prepare to cut another roll, you can use this platform to splice a new roll of material onto the one being processed, so as to realize smooth transition, save paper installation time and improve work efficiency.

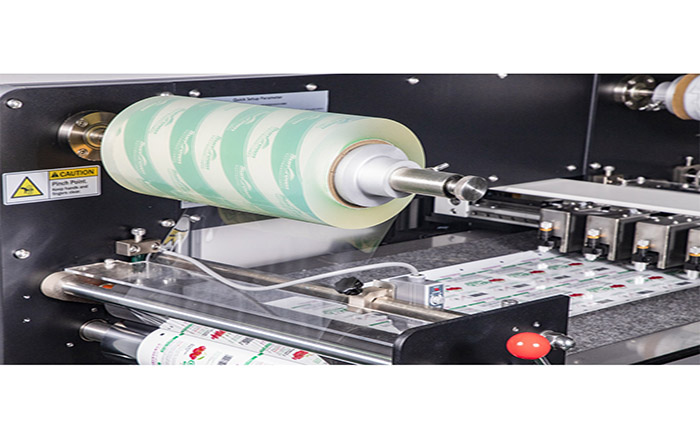

Cold lamination

Automatic lamination before die cutting, makes finishing labels more durable and more widely application.

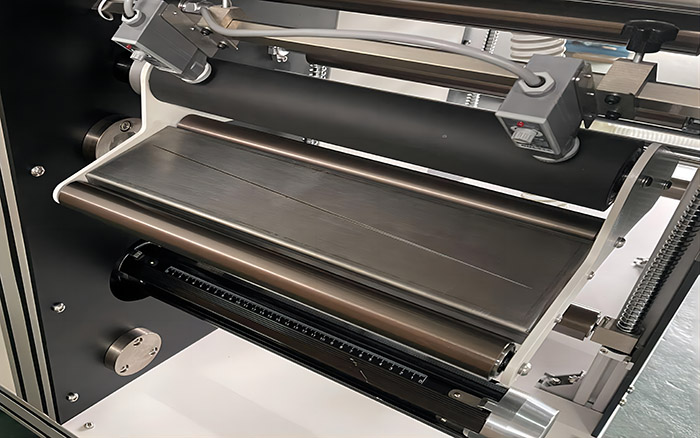

Automatic waste removal and tension system

Under the tension of the waste discharge system, the label cutting waste paper will be automatically removed and separated from the winding, so as to obtain a clean label roll for the next process.

Slitting system

Utilize square blades, automatically cut the label paper into small rolls as needed,up to 15pcs blades can be used. Maximum slitting speed can reach to 100m/min.

Automatic separate rewinding

Up and down independent winding shafts, automatically rewind the multiple label rolls after slitting.

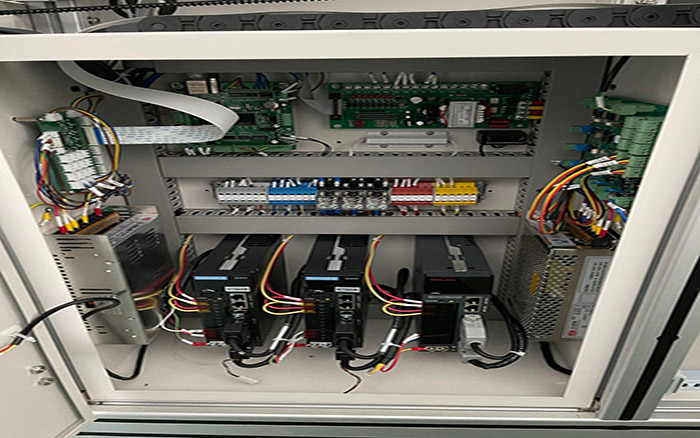

Well-organized control cabinet

Professional electrical design, orderly arrangement of components, clear circuit, easy maintenance.

Blower switch

Control the suction system. Before die cutting, press this button to start the vacuum adsorption function.

Network and USB Port

VR320 roll label cutter supports network port and U disk for die cutting files transmission.

E-stop button

If any emergency happens during machine working, press this button, the machine will stop instantly. You need to turn on the power to restart the machine.

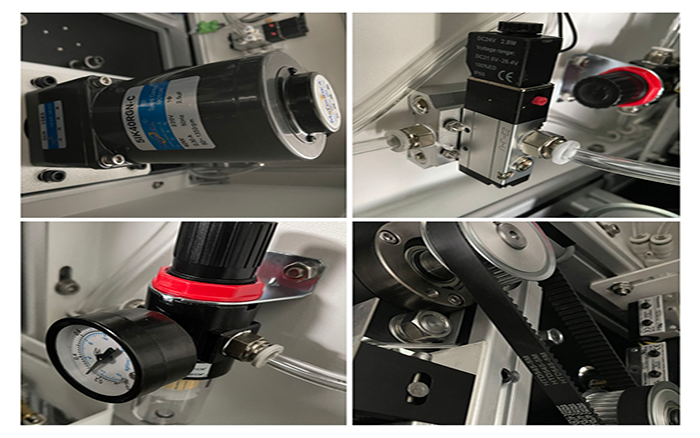

Quality components

All kinds of components used in VR320 are top quality in the industry, such as THK precision class guide rail, imported synchronous belts, Inovance servo motor, etc. Ensures machine quality and longer service life.

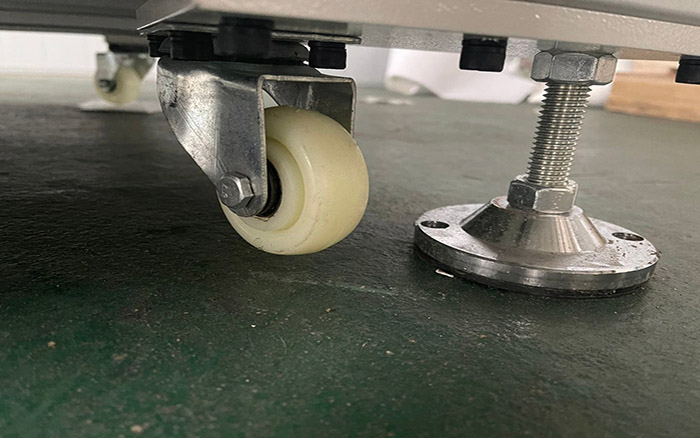

Adjustable machine foot pads

VR320 is equipped with adjustable foot pads and mobile wheels. If the ground is uneven, the horizontal position of the machine can be ensured by adjusting the foot pads. A movable wheel is installed beside each foot pad for more convenient machine movement.

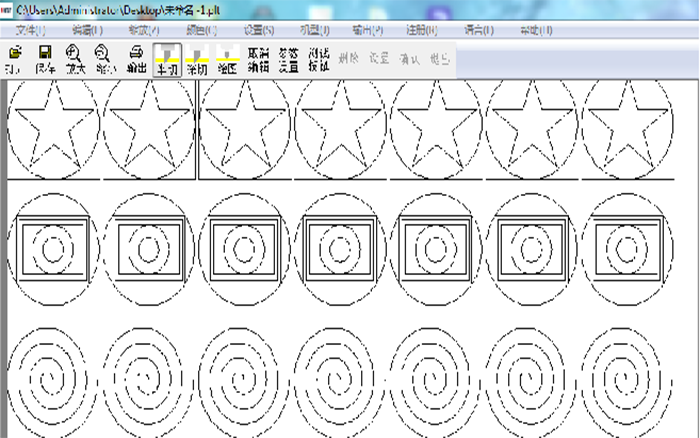

Easy-to-use software

Dedicated software support PLT & DXF format file, it can choose the knife down point according to shapes, the unique trajectory optimization is for perfect cutting.

Maximum four cutting heads.(optional)

The standard cutting heads for VR320 is 2pcs, user can choose maximum four die cutting heads as required.

Up to 15pcs Slitting units.(optional)

The standard slitting units for VR320 is 4pcs, users can choose the quantity of slitting blades as required, up to 15pcs. The slitting functions can be used alone, as slitting-only-mode.

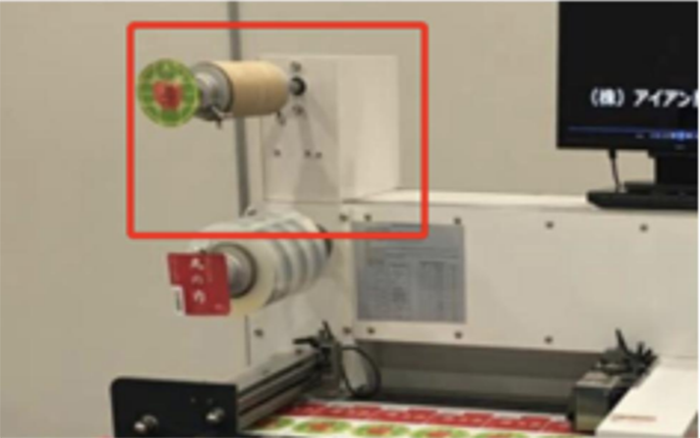

Film base paper removing device.(optional)

In some areas, there is backing paper on the cold laminating film, which can be removed before laminating by this device.

Paper Cutter RS350.(optional)

It is suitable for transverse cutting of various roll materials. Along with VR320 die cutter to achieve in-line working, with high cutting efficiency and accuracy. It can also be used independently.

Tools & Accessories

Vacuum pump

Vortex type air pump, power: 550W, speed: 2800r / min, with muffler and pressure change valve, connects to the cutting platform, fix the material on the cutting platform during the cutting process.

Blade holder

Precision blade holder, built-in bearing design, cooperate with machine blade compensation function, make cutting more smooth. Easy to install the blade and adjust the distance between the blade tips.

Die cutting blades

Special 45 degree die cutting blade, suitable for cutting 0.25 mm thick adhesive label materials such as sticker, coated paper, synthetic paper, PP, PET, etc.

Slitting blades

Tungsten steel square blades, higher cutting precision than traditional round blade.

Air compressor

VR320 uses automatic pneumatic tension system to ensure smooth paper feeding. Cooperates with vacuum adsorption system, changes the negative pressure into positive, ensure the paper on the cutting platform can move forward smoothly after each die cutting.

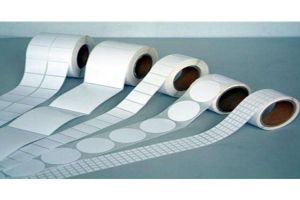

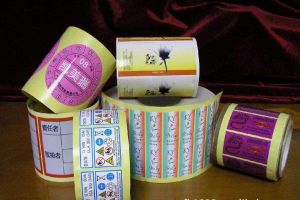

Application

Applicable Industry: VR320 roll to roll label finisher is mainly used in producing wide range of labels including blank labels, ink labels, chemical labels, beverage labels, bottled water labels, chili source labels, coffee labels, cosmetic labels, home appliance label,toiletries label, gum label, wine labels and more.

Applicable Materials: Stickers, Paper, PP, BOPP, PET, PVC & More!

Company Service: As a professional roll to roll label cutter manufacturer, Vicut believe good service always get loyal clients, 24/7 online service, all-round technical support & solutions offered within 8 hours. Remote training, available user manual and operation video are provided.

Working Samples:

|  |  |  |

|  |  |  |

|  |  |  |

Packing photos

|  |  |  |