vicutcnc@cncvicut.com

vicutcnc@cncvicut.com

+86 551 6577 4134

+86 551 6577 4134

Get A Quote

Get A Quote

vicutcnc@cncvicut.com

vicutcnc@cncvicut.com

+86 551 6577 4134

+86 551 6577 4134

Get A Quote

Get A Quote

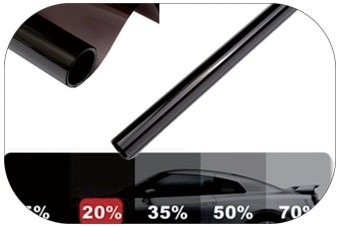

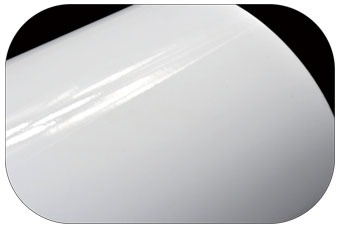

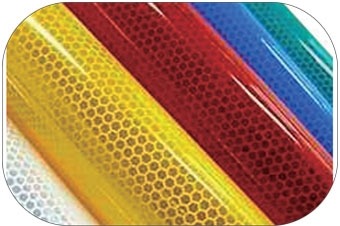

VICUT GC series roll feeding cutting plotters offer advanced solution for users from automotive aftermarket, road safety, signage, graphic and counter-top installation. The vinyl cutter plotter is capable of processing paint protection film (PPF), window tinting,regular reflective film, sandblast resist rubber, card paper, self-adhesive vinyl, Amberlith and Rubylith, etc.

KEY FEATURES

Stable Accurate Tracking for 7000mm /23ft

Leading most of the competitors, the GC series if able to do stable long length tracking for 700mm/23ft, which is an important feature for high-level processing, it is ideal for big sign, pattern making.

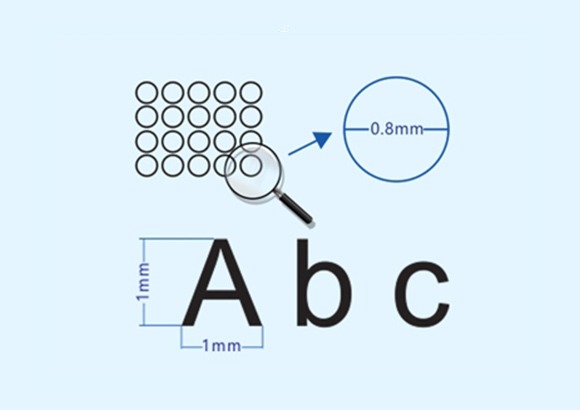

Cutting small text strings accurately

It is able to cut small text strings, such as circles sized Φ0.8mm, characters sized 1x1mm and numbers sized 3x3mm, and it is easy to tear off the scraps.

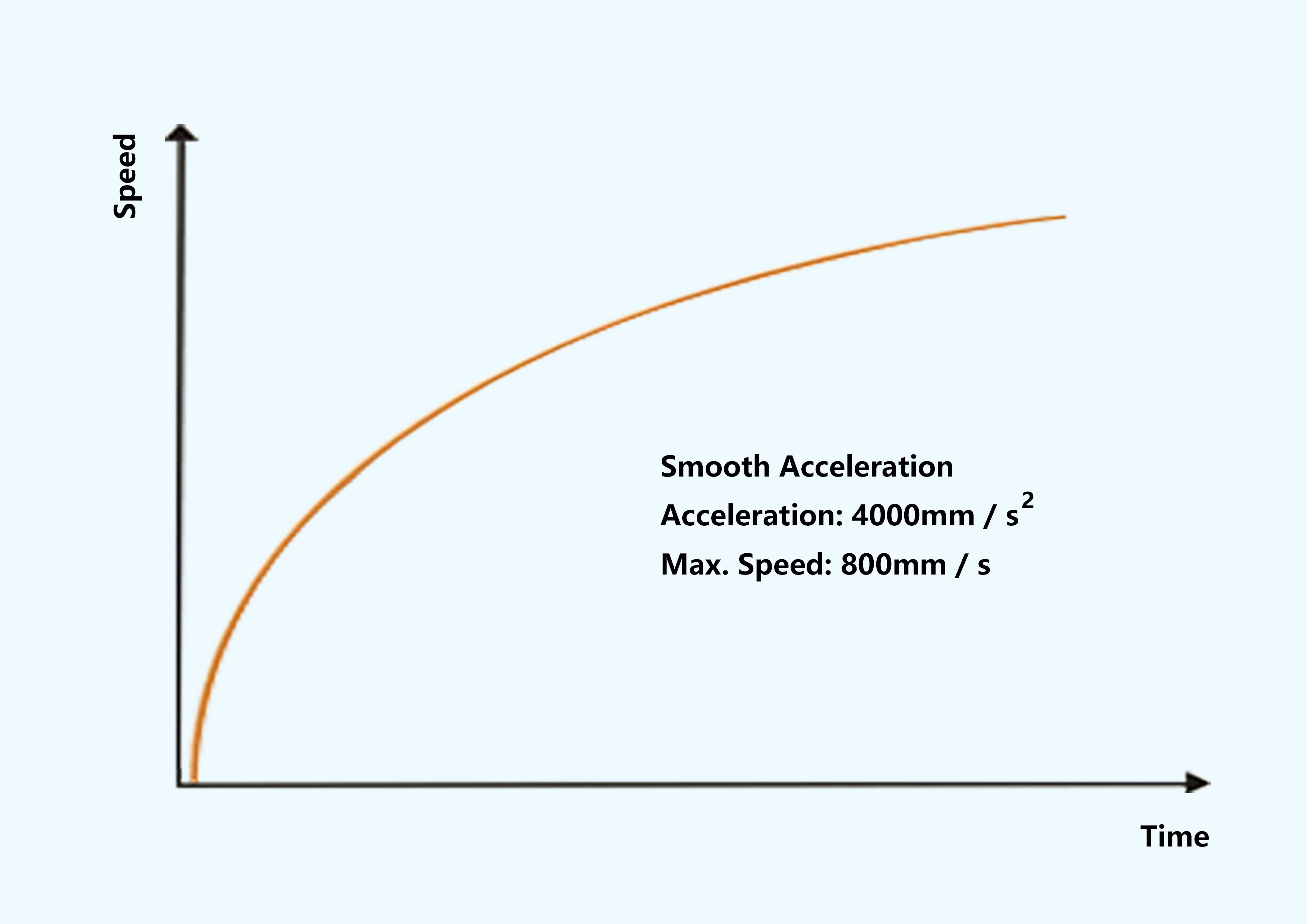

Fast speed

Max.cutting speed reach to 800mm/s, acceleration speed reach to 4000mm/s.

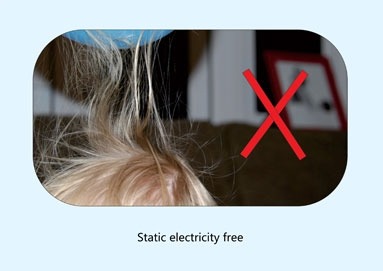

Static electricity free

The problem of friction electrostatic interference when cutting soft thin materials is solved on GC cutting plotter.

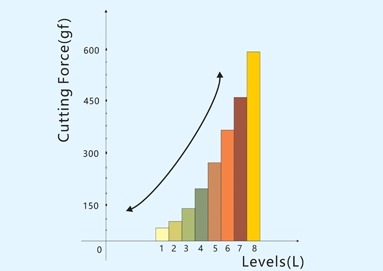

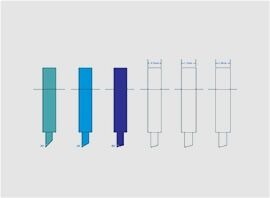

Cutting force in 8 Steps

User is enabled to put different colors for different cutting paths, and set the processing sequence as color sequence, and different paths are processed by different steps of cutting force.

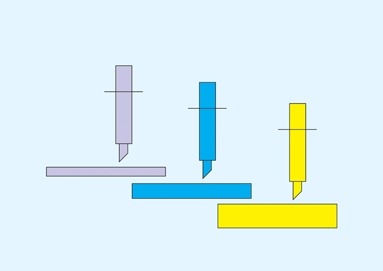

Multiple layers solution

For medias with multiple layers, different cutting force is applied for different layer.

Handshake Protocol

We supply Software Development Kit / SDK to match with client’s software, which deepen cooperation between Gunner and Professional clients.

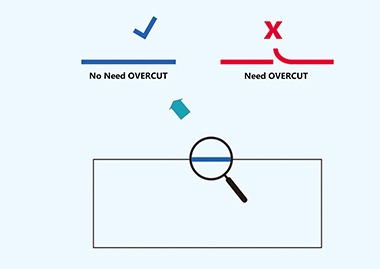

No Need OVERCUT

On every cutting path, the start point and end point coincide accurately, while no need any OVERCUT.

DXF Direct Output

Unnecessar

Technical Parameters

Model | GC-140 |

Max. Cutting Width (Non-contour Cutting) | 1290mm |

Max. Cutting Width (Contour Cutting) | 1220mm |

Max. Mountable Media Width | 1440mm |

Min. Mountable Media Width | 70mm |

Max. Cutting Speed | 800mm/s |

Max. Cutting Force | 450G in 8 steps |

Cutting Force Setup | Adjustable in every 1gf |

Drive | Servo |

Mechanical Resolution | 0.0125mm |

Min. Circle Diameter | 0.8mm |

Min. Character Size | 1x1mm |

Min. Number Size | 3x3mm |

IOS | Win10/8/7/XP |

Memory Buffer | 2MB |

Software | Windows Driver, SignWork Pro, CAD to Plot Pro |

LCD | English |

File Format | HP-GL,PLT |

Port in Standard | U-disk, USB,RS-232 |

Registration Marks Sensing | CCD Camera |

Power Input | 90V-240V AC,50-60Hz |

Power Consumption | 60w |

Cutter Holder/Pen Holder | 1 for each |

Cutter Blade Diameters | 2.0mm |

Cutter Blade Angles | 30°,45°,60° |

Types of Pen | Water based fiber-tip pen & Oil based ball pen |

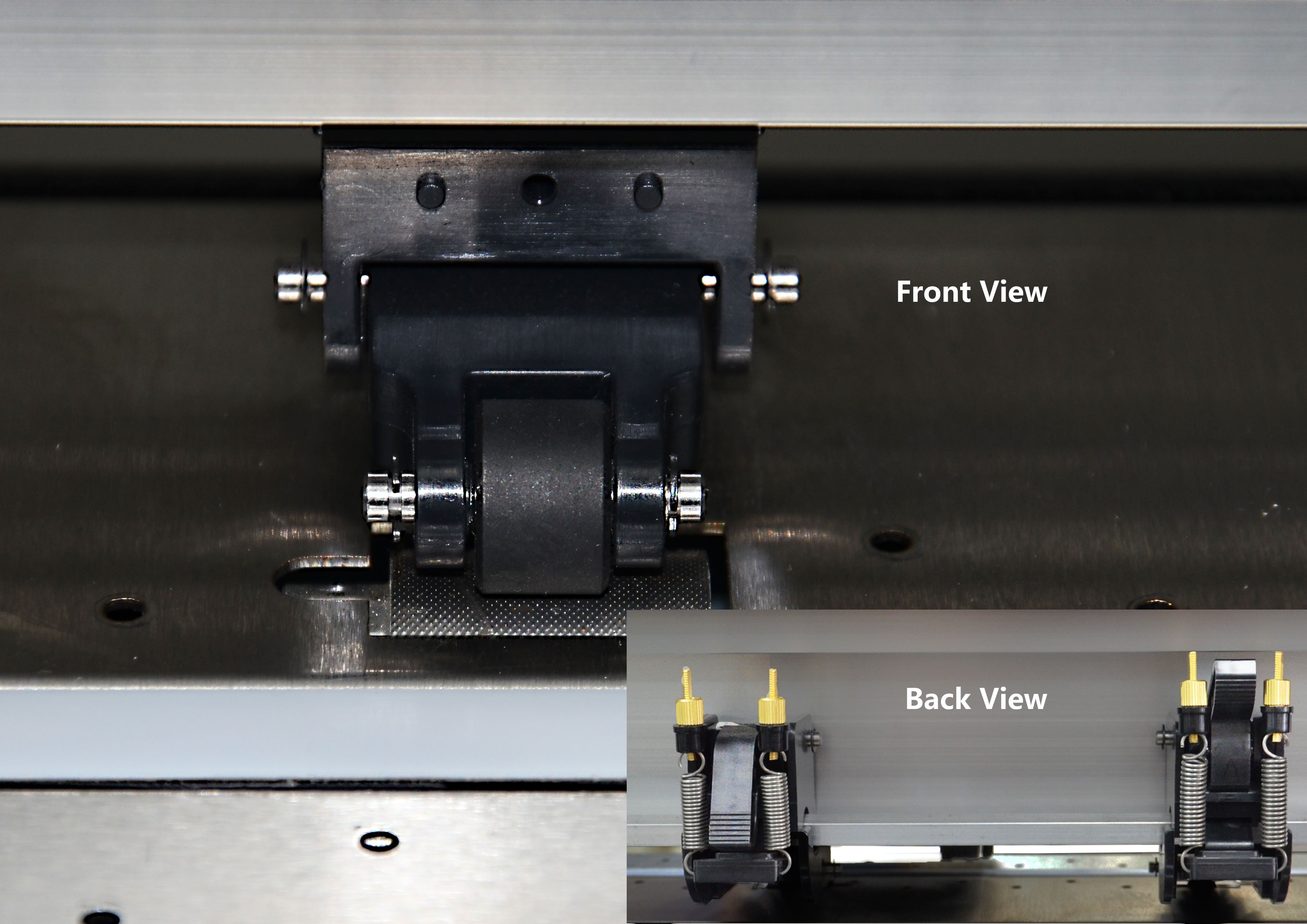

Method to Fix Material | Push rollers |

Media Basket | Included |

Cloth Basket | Option |

G.W./N.W. | 64/48kg |

Package Size L-W-H | 171x40x57cm (0.4CBM) |

Details Description

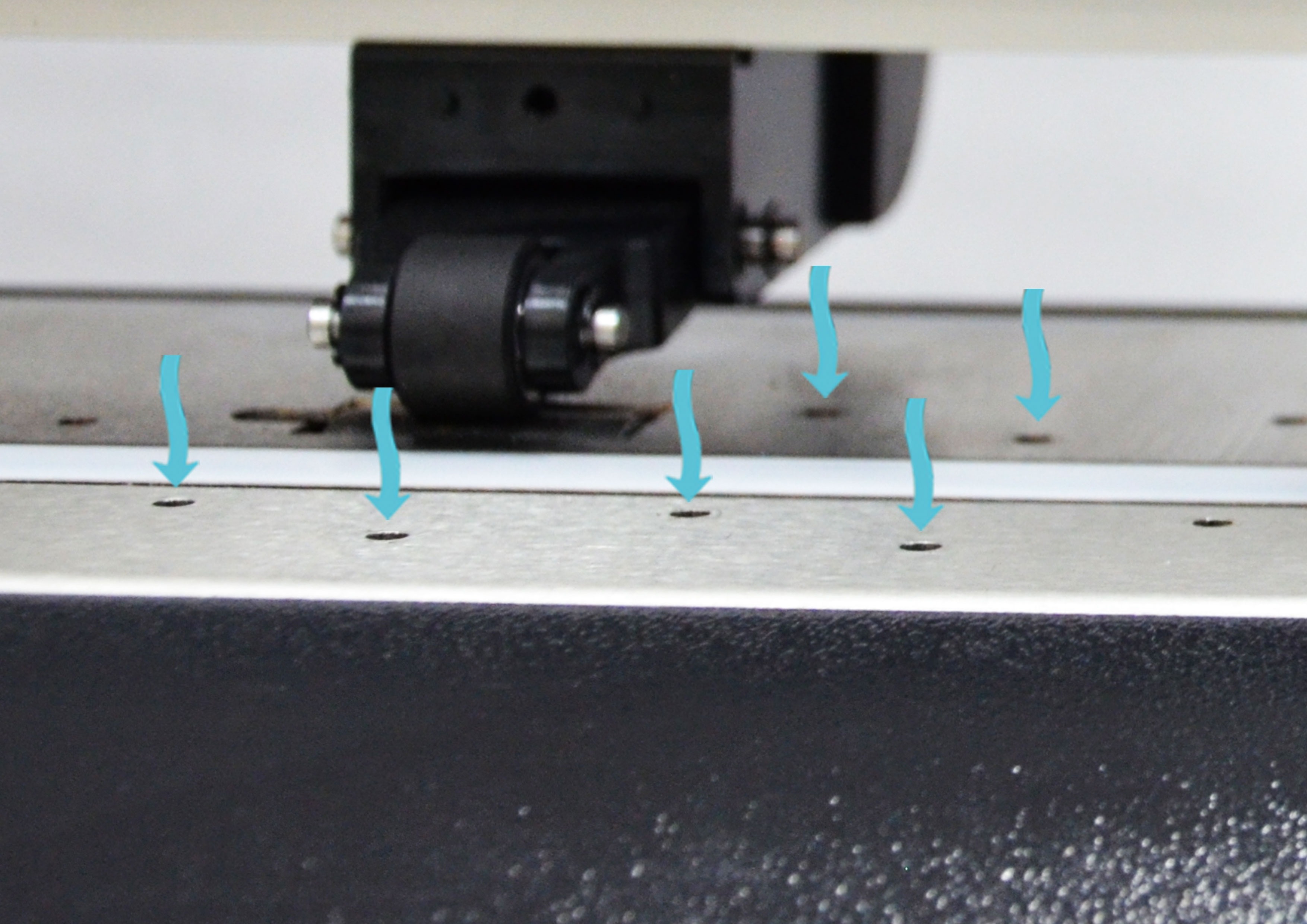

Accurate Rigid Push Rollers

Our push rollers are made from hard materials, it is capable of working accurately for long time. The push rollers can be set to two pressure levels: Strong/ Low.The combination of accurate rigid push rollers, precise material feeding rollers and quality media bracket rollers ensure stable long length tracking of material.

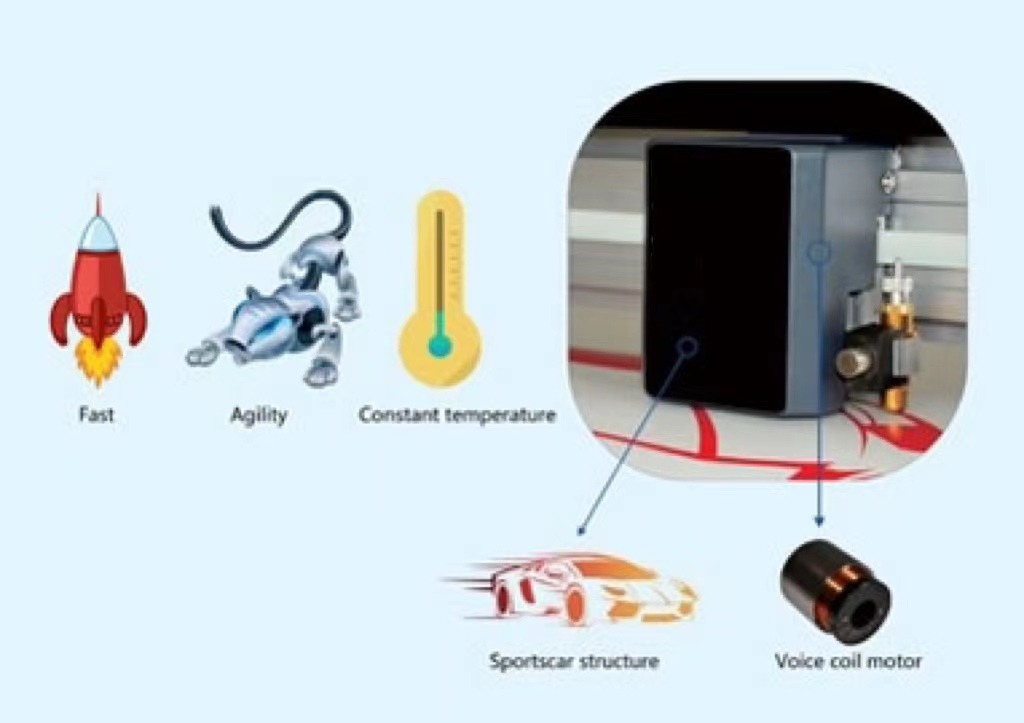

Advanced Tool Carriage

Tool Carriage is one of the most important parts of the machine. Taking the sport car structure, driven by silent voice coil motor, GR8000 plotter’s tool carriage is featured as fast, more agility and no overheat for long-term non-stop operation.

Suction Cutting Table

Dense air inlets & strong air flow to hold down the media flatly and tightly against the table top so that the tool carriage can perform fast, accurate cutting / plotting.

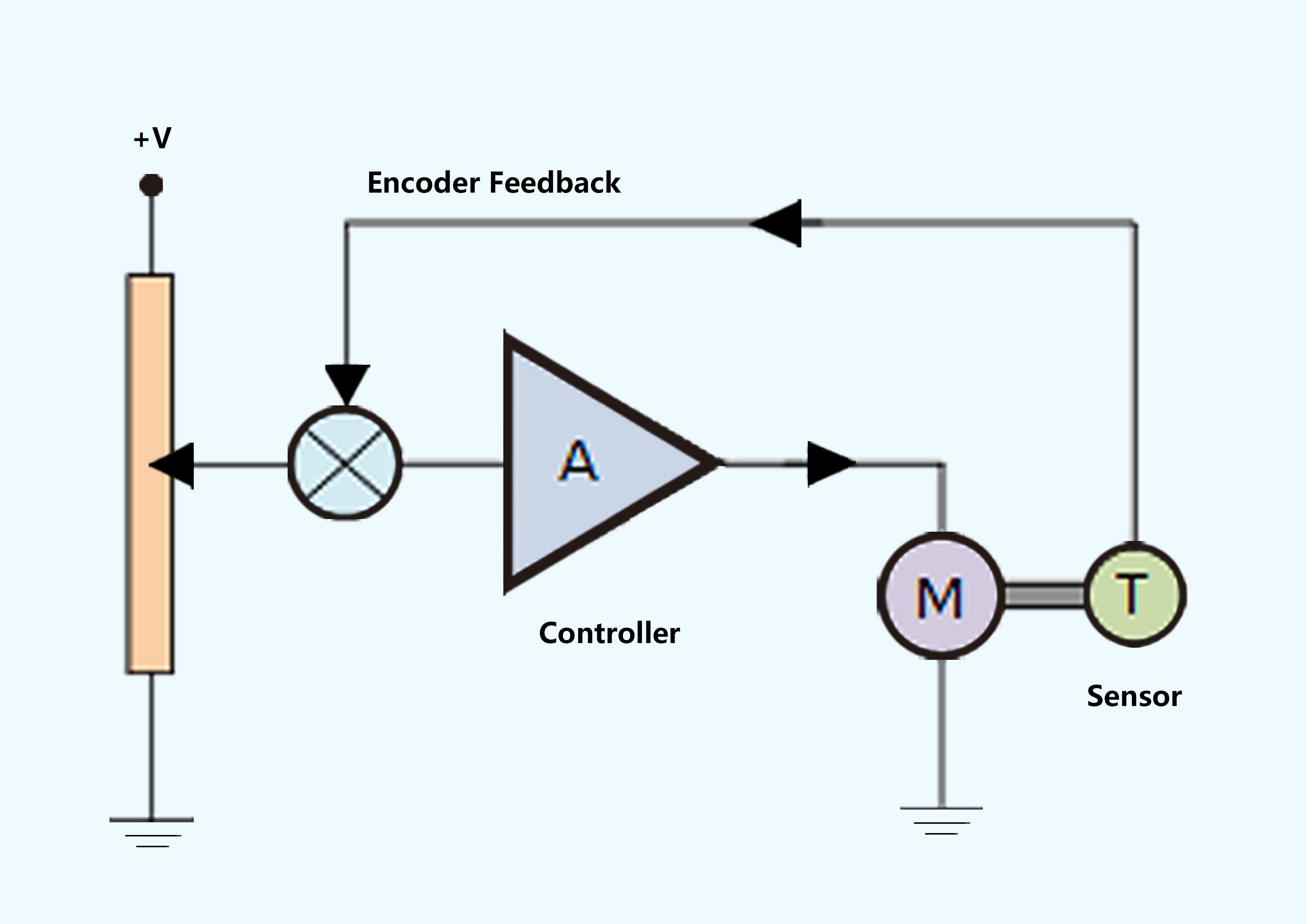

Servo Motor / Closed Loop Control

Cutting / Plotting will be stopped when tool carriage is overloading, it is an important safety feature to protect tool carriage when media is jammed.

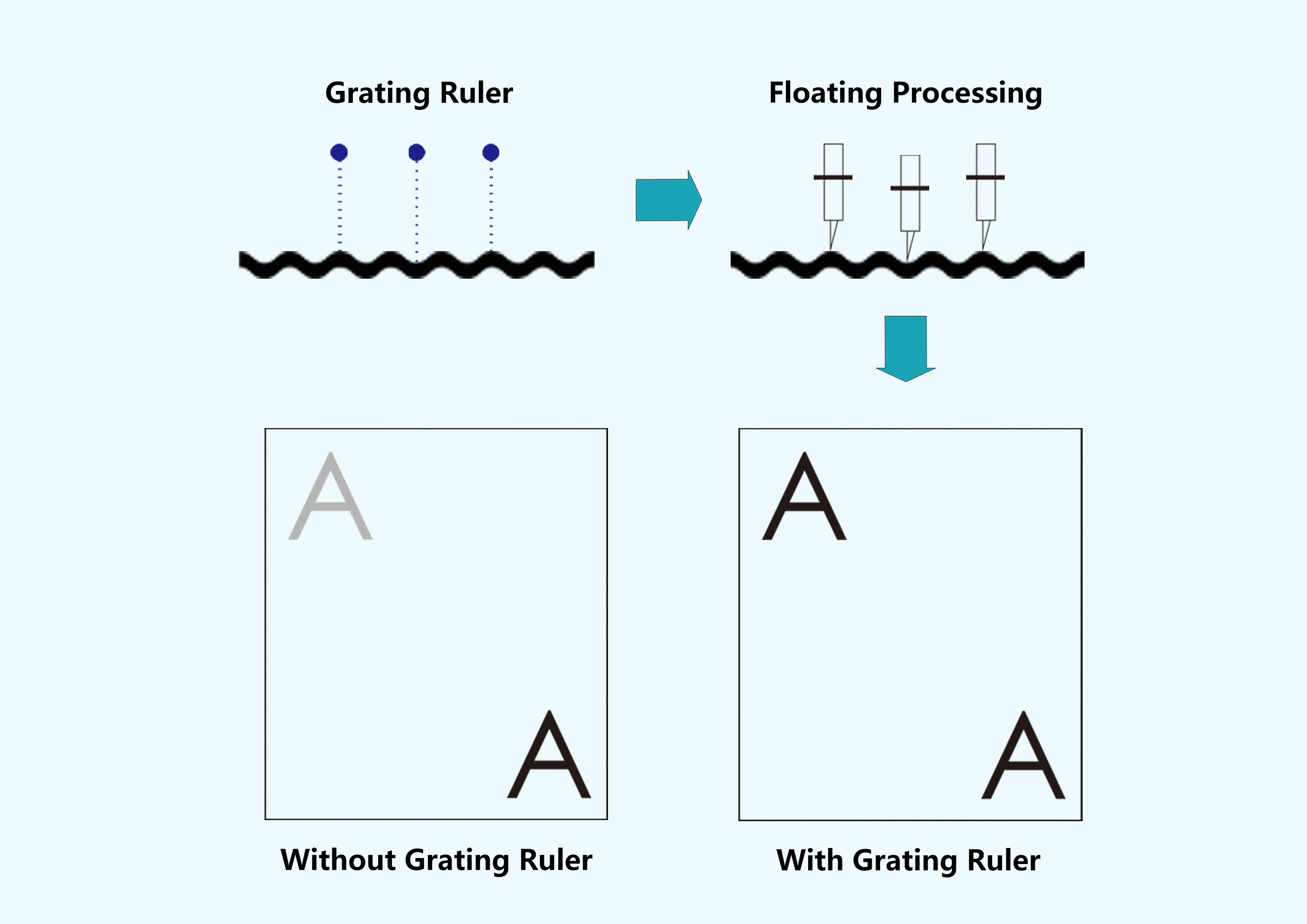

Grating ruler

It is inevitable that the cut table or material surface is not at the same height from point to point, we take Grating Ruler, a precise optical device, to measure the distance between blade tip and material surface in real time, and the cutting depth is adjusted in every 0.01mm by the controller in real time according to the value of distances measured. Subsequently, the blade travels up and down as material surface goes up and down in order to keep the same cutting depth at any position of that tool path across entire working size.In short the cutting depth is consistent; you will not see different shades.

Electrostatic elimination

The complete elimination of static interference is especially important for PPF installers. VICUT GC series cutter plotter eliminates the static interference successfully having been tested year-round in different weather conditions.

Quality components

For more outstanding performance and long-term reliable working, we only use world class brand name components such as BANDO belt, MINEBEA bearing, etc.

Clean Smooth Edge Quality

The Grating Ruler and correspondent cutting force management deliver clean smooth edge quality, even for the most complex jobs. GR8000 series is able to cut small text strings and it is easy to peal off the waste material, which cut down workload greatly for the users.

Making Blade-tip Compensation by chip

Our system makes blade-tip compensation by hardware(main board) instead of oftware, the cutter works with constant high precision no matter what kind of CAD / CAM software is applied.

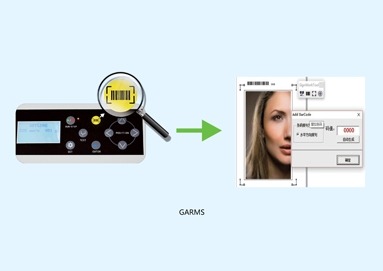

Scanning Bar-code when offline

One-click to spot the cutting job from those saved in the USB memory by scanning the Bar-code which is printed in media, while not requiring connecting to PC. This function is especially helpful to increase the productivity when there are many files stored in the USB memory.

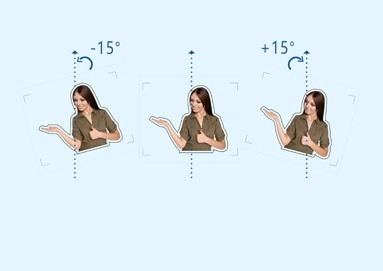

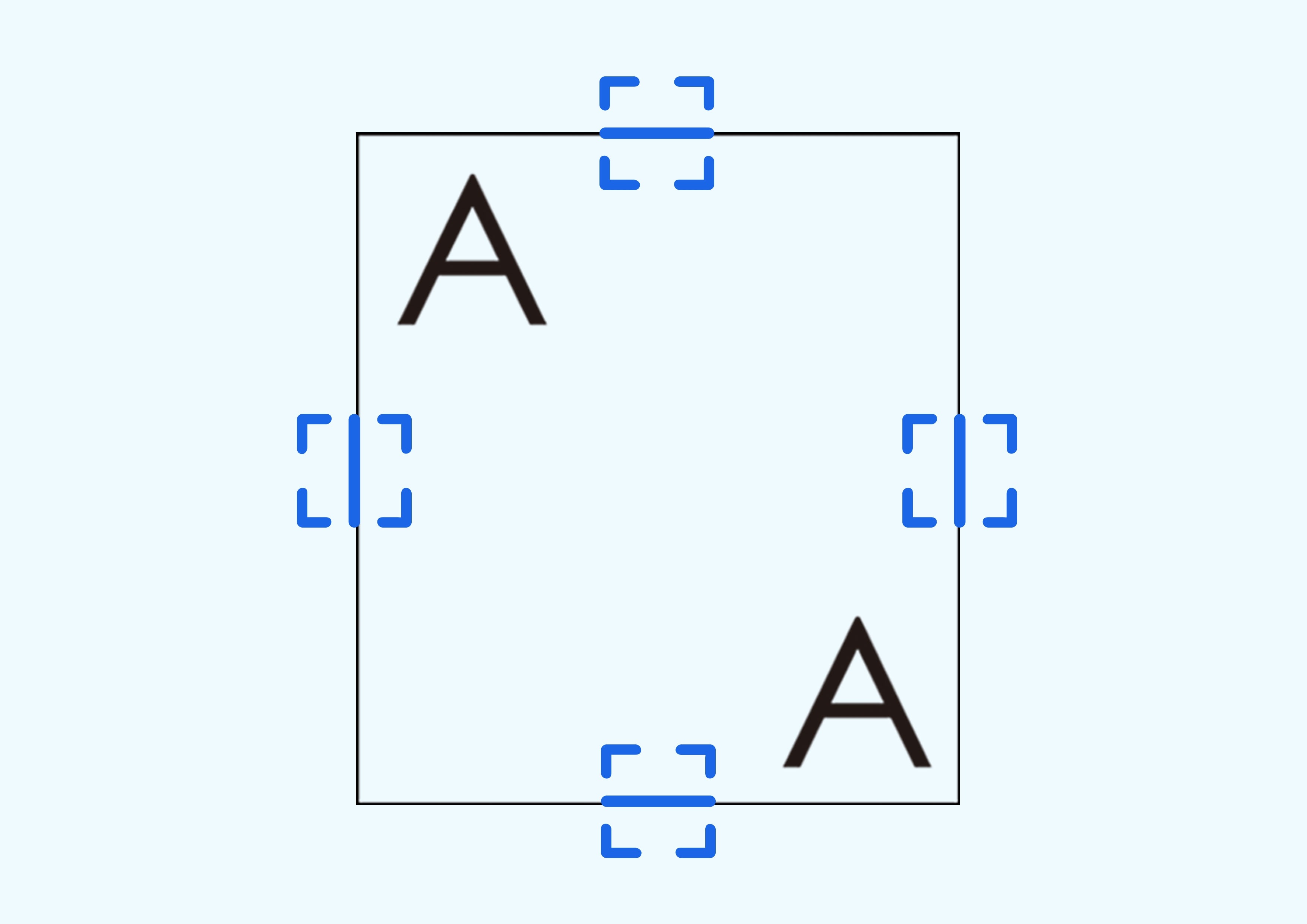

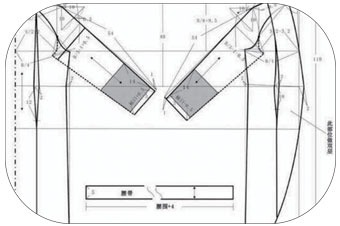

Advanced Registration Marks Sensing

One-click to add registration marks and generate contour(s) of the object(s).

One-click to read the registration marks and carry out the contour cutting.

To match the cutting path(s) and contour(s) to the best, fine adjustment with either keypad or software is available. If material is placed askew (≤15°), the cutter is still able to work fine, this feature helps to save time.

Half Cut / Perforation Cut

Half cut / Perforation cut are available, every time you may carry out either one or both.

Dotted lines cutting

Dotted lines cutting is applicable for medias with 2 layers typically and also kinds of paper.

One-click to Install Print Driver

One-click to install print driver and printout with USB, send cutting job from any CAD software that with printer feature. Our print driver works with Windows 32/64 bit.

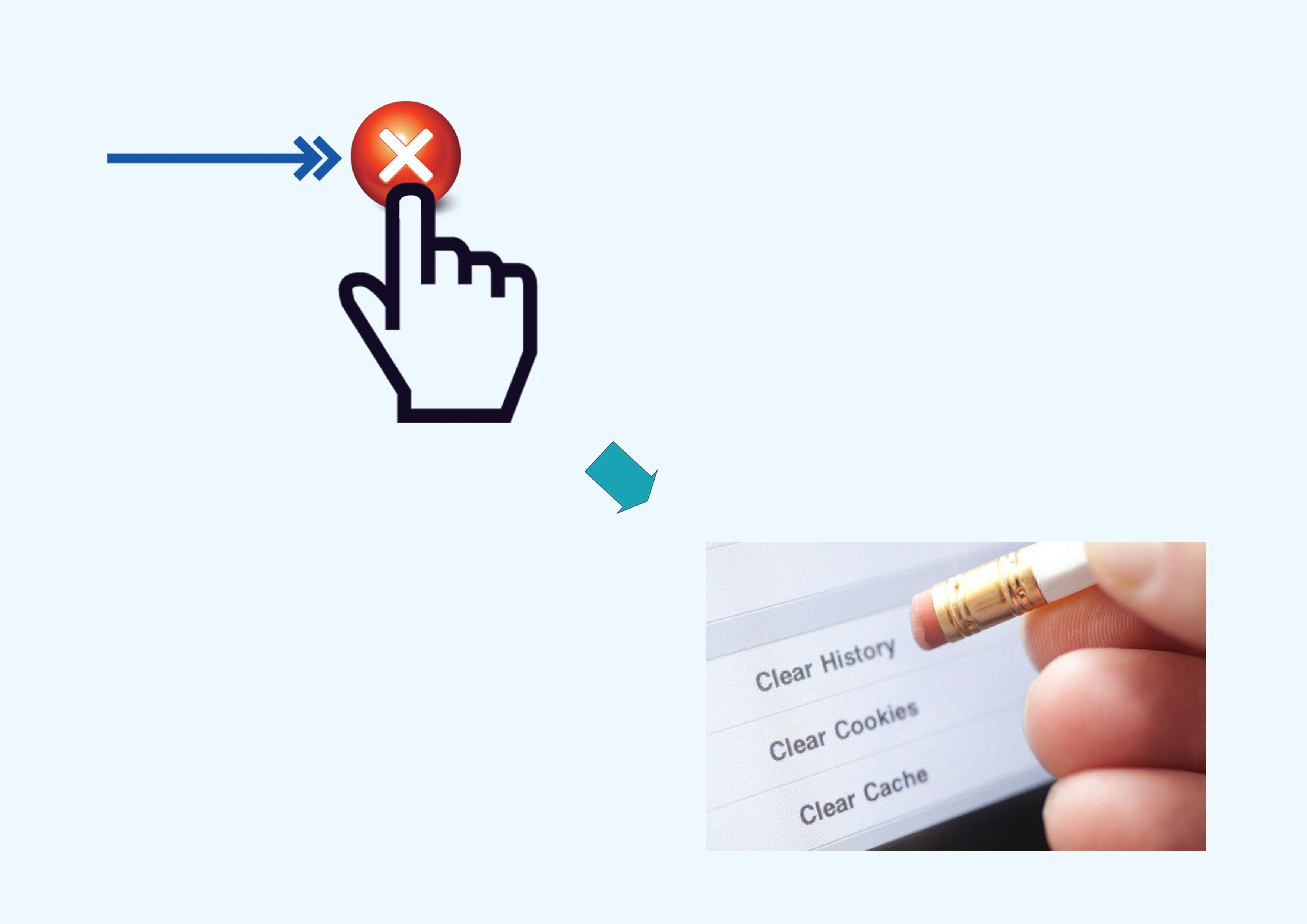

One-click to Clear History

One-click deletion button for the currently print document.

Transfer working files by USB memory and support repeated operation.

Leading Calibration

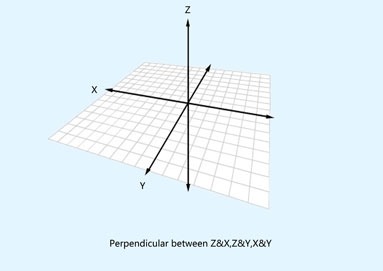

Industry leading technology is applied to calibrate the perpendicular between different axes and the parallelism between gantry and cut table.

Compatible with AutoCAD, AI, Coreldraw and Flexisign

Leading the same industry, we make software by our-self, we are able to adapt our system to the latest version of popular CAD / CAM software, such as AutoCAD, Adobe Illustrator, Coreldraw and Flexisign and more.

Media Sensor(optional)

It is applied to measure the size of media, the cutting/ plotting operation won’t be carried out if media size is not big enough for the contents, and controller will ask operator to enlarge the media or decrease the size of contents. Media sensor helps greatly in saving media and increasing efficiency.

Tools & Accessories

Fine Blade Holder

This precision engineered components sits in the advanced carriage and holds the cutting blade of choice. The tool is manually adjustable to obtain the desired amount of “ blade out”for the job in hand.

Calibration Tool

Used at set up and then periodically, to calibrate the cutter.

Cutting Blades

Various blades available for different applications. Angle:30°/Φ2.0mm for thicker media or smaller character. Angle:60°/Φ2.0mm for reflective film.

Application

APPLICATIIONS

Various printable self-adhesive materials can be used. Such as, Photo Paper, T-shirt Transfer Paper, Photo Quality Inkjet Card, Stickers, Glossy paper, Transparent Films, etc.

Working Samples

Packing photos