vicutcnc@cncvicut.com

vicutcnc@cncvicut.com

+86 551 6577 4134

+86 551 6577 4134

Get A Quote

Get A Quote

vicutcnc@cncvicut.com

vicutcnc@cncvicut.com

+86 551 6577 4134

+86 551 6577 4134

Get A Quote

Get A Quote

The VICUT VR320F digital die cutter, updated from VICUT roll to roll label cutter VR320X, is the most affordable digital sticker cutting system for small and medium production. It is a collection of web guide, laminating,die-cutting, and automatic waste removal system, best solution for roll-to-pieces digital finishing. No cutting dies required, fast and precise , fully satisfy on-demand sticker cutting. Also can be used for regular roll to roll label kiss cutting system.

High-precision CNC die cutter for label & sticker finishing — roll-to-roll + flatbed, 0.1mm accuracy, cold lamination, automatic matrix removal. Get a quote!

KEY FEATURES

Combination of flatbed and roll to roll mode

Roll to roll kiss cutting labels &full cut roll into pieces

Automatically allocate the number of cutting heads based on label design

Web guide system to ensure accurate paper feeding

Cold lamination for extended labels durability

Automatic conveyor system for matrix removal

Technical Parameters

The VR320F CNC die cutter is a compact, cost-effective digital die-cutting solution for small-to-medium label and sticker production. It combines roll-to-roll rotary finishing with flatbed capabilities, eliminating the need for cutting dies and delivering fast, repeatable, on-demand cutting.

Top digital finishers from VICUT focus on roll-to-roll finishing, die-less contour cutting, and integrated lamination/slitting. The VR320F aligns with these industry trends while offering an affordable entry point for small/medium producers seeking cnc die cutter functionality without the premium price tag.

Model Name | Digital Die Cutter VR320F |

Maxi. roll diameter | 450mm |

Cutting media width | 150--340mm |

Max.contour cutting width | 330mm |

Max. contour cutting length | 400mm(segmentation cut to 1.2m for kiss cutting) |

Mini. cutting length | 10mm |

Max. die cutting speed | 6m per minute (depends on label shape and size) |

No. of die cutting heads | standard 4 heads |

Cutting type | full cutting, kiss cutting |

File format | DXF, PLT |

Die cutting blades | tungsten steel blades |

Die cutting precision | 0.1mm (duplicate) |

Die cutting mark registration | electric eye (CCD camera is optional) |

Matrix removal | automatic conveyor system |

Roll Rewinder | 1pcs |

Slitting device for roll | optional |

Data transfer method | PC transfer via USB, U-disk |

Working voltage | 110-240VAC, 2000W |

Machine dimension | 160*100*136cm(L*W*H) |

Weight(N.W/G.W) | Machine: 580kgs/670kgs Vacuum pump: 10kgs/16kgs |

Packing size | Machine: 170*115*157cm Vacuum pump: 450*450*500mm |

Optional function | Linear system,Crack and peel assy |

· Roll-to-roll + flatbed modes for kiss cutting, full cutting, prototype labels, and flexible finishing workflows.

· Four automatic cutting heads for intelligent tool allocation and higher cutting efficiency.

· High-accuracy registration with digital electric-eye positioning for stable contour tracking.

· Vacuum suction cutting platform ensures smooth feeding and precise cutting without material shifting.

· Inline cold lamination improves durability and scratch resistance, with optional linear laminating system.

· Automatic matrix removal reduces manual labor and speeds up post-processing.

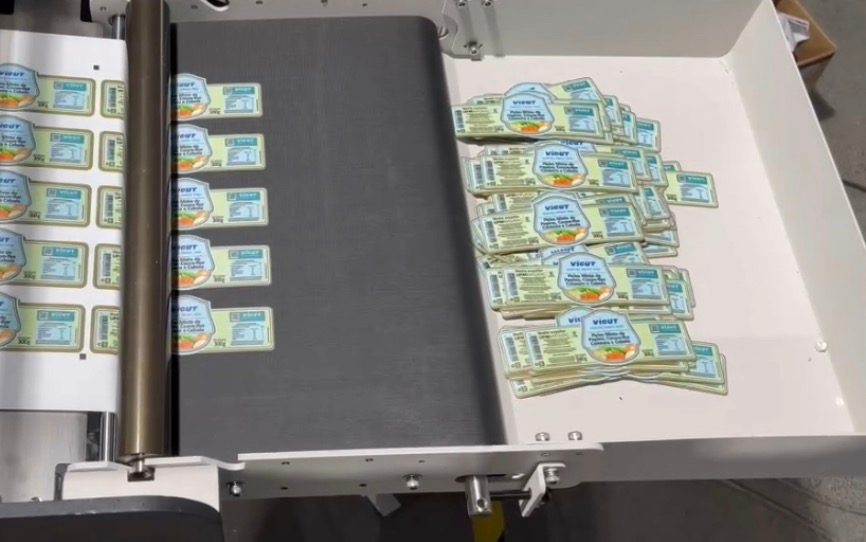

· Conveyor output system for continuous production and easier collection.

· Easy-to-use software supporting DXF and PLT formats, with automatic blade adjustment and simplified setup.

As one of the professional label die cutting machine manufacturers, we focus on delivering stable performance, precise cutting accuracy for global label converters and digital printing businesses. From machine configuration to after-sales support, our engineering team ensures every CNC die cutter meets industrial production requirements and provides consistent results across different materials and job types.

Details Description

Multiple die cutting heads automatic adjustment distance

VR320F works with multiple die cutting heads, standard 4 heads work at the same time, highly increase working efficiency.

User friendly operation panel

The main operation buttons are integrated into the same panel for easy operation. Touch screen interface, sensitive response, easy to set machine parameters.

Digital cutting positioning sensor

The positioning sensor scans the marked points printed on the material to obtain the cutting dies information and feed it back to the machine control system, so as to realize the digital cutting.

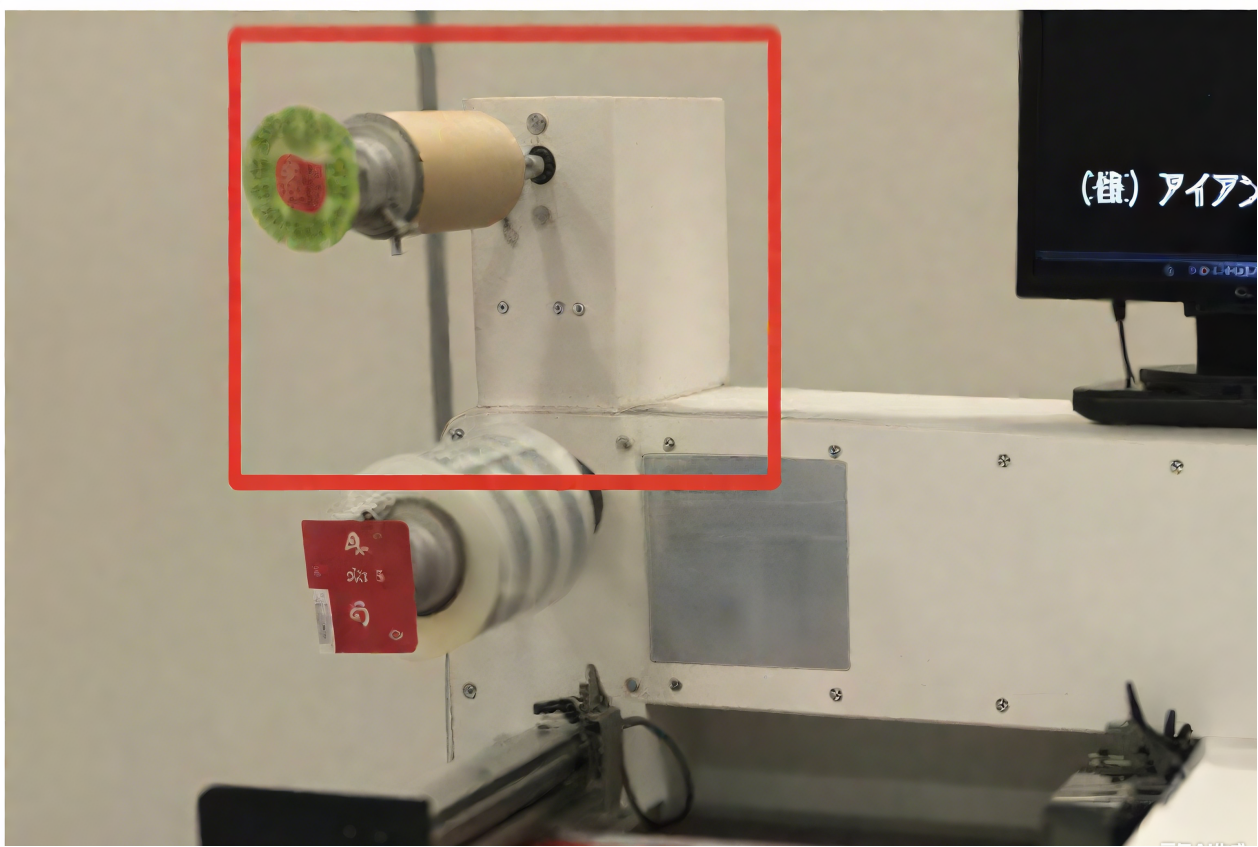

Automatic web guide system

Adopting advanced ultrasonic correction system to ensure smooth paper feeding without deviation, laying the foundation for precise cutting in the next step. Web guide platform also can be used for splicing media.

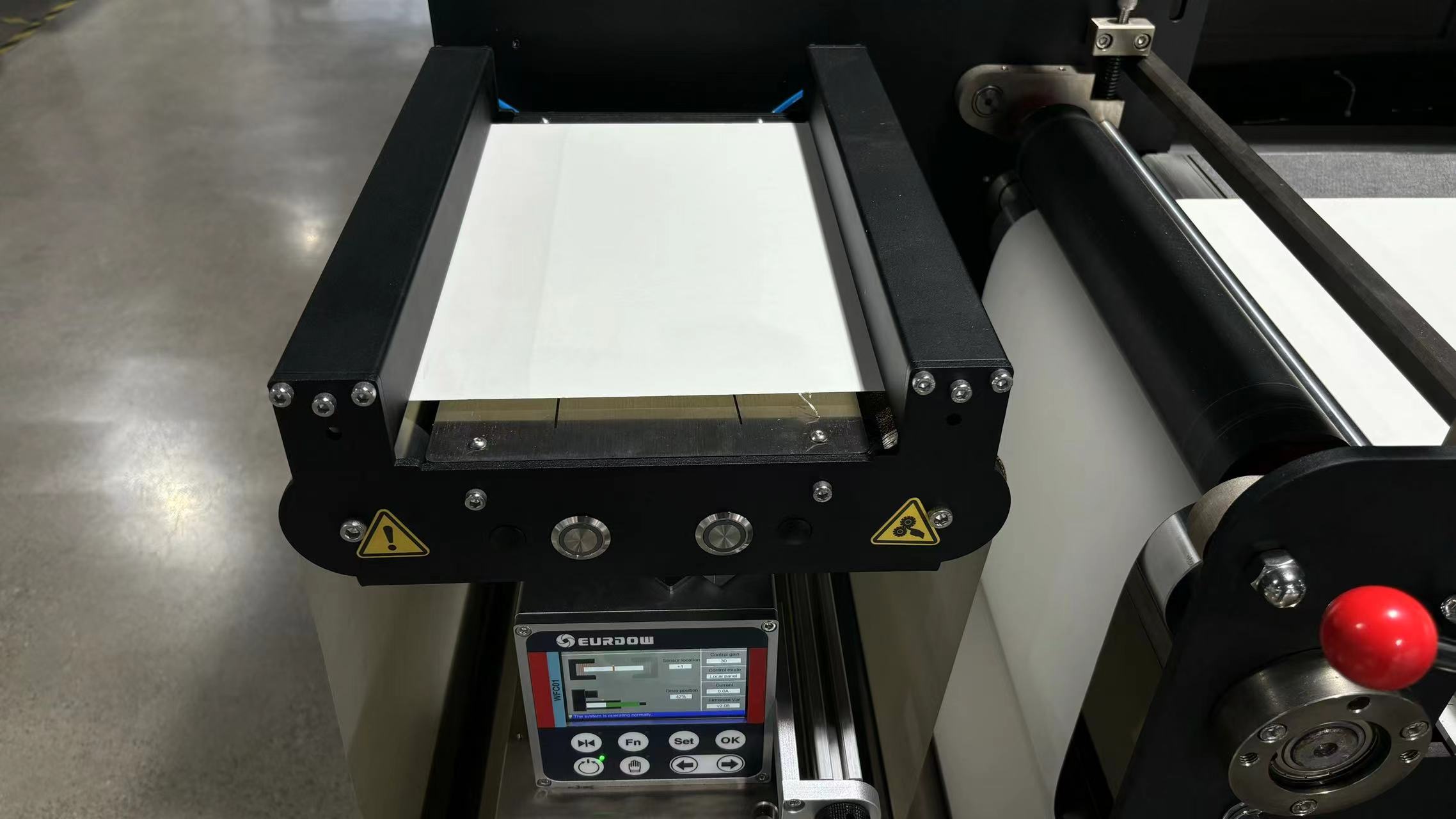

Vacuum suction cutting table

Vacuum inhaling cutting platform, the adsorption function starts along with die cutting, and automatically loosening valves after cutting finishes, to ensure cutting accuracy and smooth paper feeding.

Cold lamination

Automatic lamination before die cutting makes finished labels more durable and expands their application range.

Conveyor table tor collecting sticker pieces

With automatic conveyor system, the cutting waste paper will be automatically removed so as to obtain a clean label pieces for the next process.

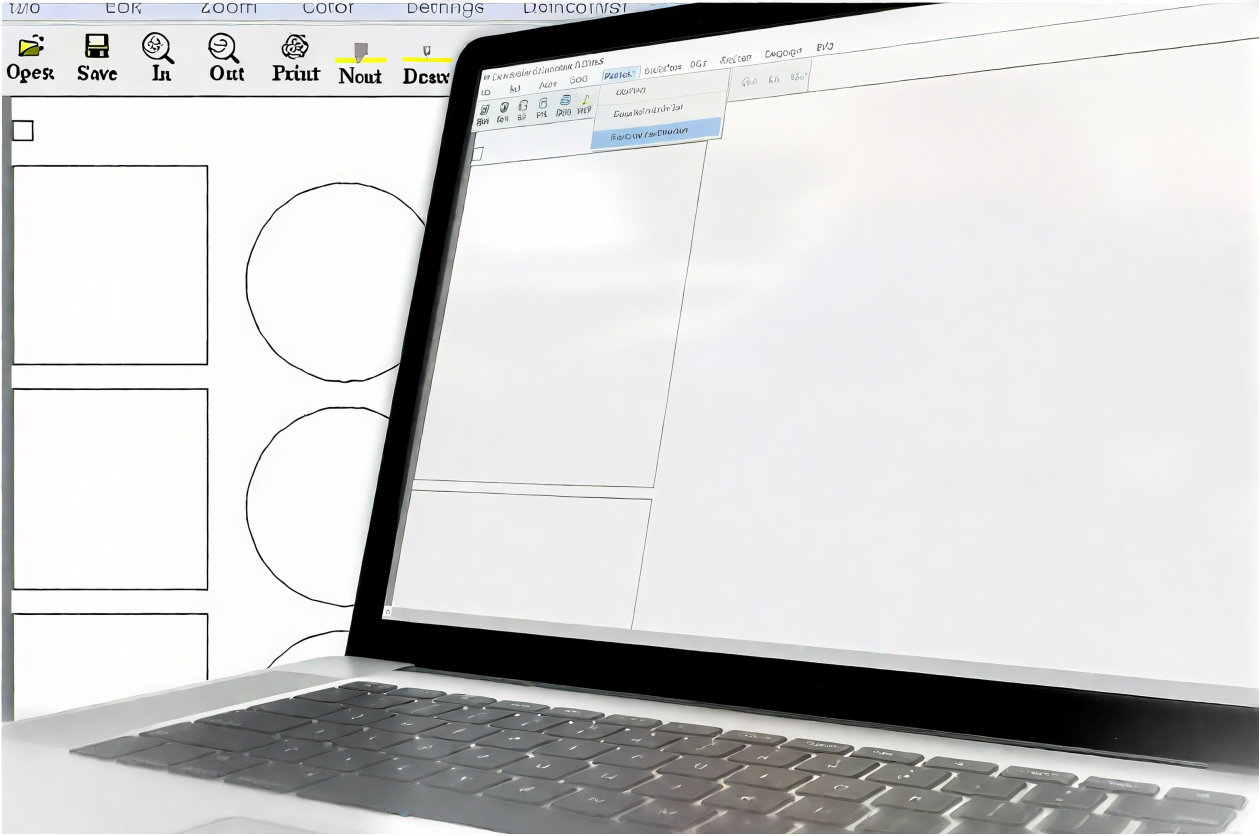

Easy-to-use software

Dedicated software support PLT & DXF format file, it can choose the suitable blades and adjust the blades distance automatically according to different designs, no need manual adjustment

Laminating linear system(Optional)

In some areas, there is backing paper on the cold laminating film, which can be removed before laminating by optional linear system.

Tools & Accessories

Vacuum pump

Vortex type air pump, power: 550W, speed: 2800r / min, with muffler and pressure change valve, connects to the cutting platform,fix the material on the cutting platform during the cutting process.

Blade holder

Precision blade holder, built-in bearing design, cooperate with machine blade compensation function, make cutting more smooth. Easy to install the blade and adjust the distance between the blade tips.

Die cutting blades

Special 45 degree die cutting blade, suitable for cutting 0.25 mm thick adhesive label materials such as sticker, coated paper, synthetic paper, PP, PET, etc.

Air compressor(Optional)

Used for automatic shaft tension control. Connect the 8mm compressor tube to the machine.

Application

Applicable Industry: VR320F flatbed & roll to roll label finisher is mainly used in producing wide range of stickers which can be used for signs, labels, etc.

Applicable Materials: Stickers, Paper, PP, BOPP, PET, PVC & More!

Packing photos