vicutcnc@cncvicut.com

vicutcnc@cncvicut.com

+86 551 6577 4134

+86 551 6577 4134

Get A Quote

Get A Quote

vicutcnc@cncvicut.com

vicutcnc@cncvicut.com

+86 551 6577 4134

+86 551 6577 4134

Get A Quote

Get A Quote

Conveyor belt, named for its ability to automatically convey products in a specific direction. VICUT has developed automatic feeding digital flatbed cutting machine with conveyor table, which plays a great role in related areas. Flatbed cutting plotter is mainly used for cutting soft media without need of a die, and it is absolutely efficient solution for punching, cutting, semi-cutting, die-cutting and marking, etc.

We now introduce you its unparalleled performance.

Scale on digital flatbed cutting machine is used to ensure same cutting depth. On every cutting path, start and end points coincide exactly, no over-cutting. The scale and corresponding cutting force management system provides clean and smooth edge performance for even the most complicated job. For media with multiple layers, machine also applies different cutting forces to different layers.

Powerful airflow to flatten materials tightly to the table, allowing knife holder moving fast, cutting and plotting precisely. Eliminates electrostatic interference thus to increase qualified products rate.

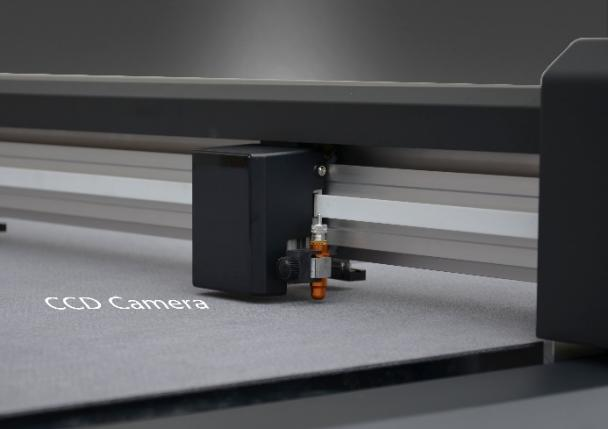

The conveyor supports long distance and seamless cutting. Combined with CCD camera, nesting or contour cutting can be done quickly and precisely. Moreover, with the combination of CCD camera and related software, machine can detect complex contourless lines quickly and efficiently, solving problems which caused by human positioning errors or poor printing quality.

And if tool holder was overloaded, cutting or plotting would be automatically stopped, this is an important safety function to protect tool holder when the material jammed.

The GR series flatbed cutter controller operates with advanced algorithms which can be easily upgraded and customized against various applications in the future.

One-touch delete button completely erases the document from buffer memory to avoid information leakage.

And, blade tip compensation is built into main board, so cutter can work at constant high accuracy situation no matter what CAD/CAM software you apply, such as AutoCAD, Adobe lllustrator, CorelDraw and Flexisign.

The distance between blade tip and material surface is measured in real time. Based on the measured distance value, controller adjusts cutting depth in real time at a rate of every 0.01 meters. Then blade moves up or down synchronously with material surface so that the same cutting depth can be maintained at any position, in that toolpath throughout the working dimension.

In short, the cutting depth is consistent and you won't see different tones.

One-click identification, from cutting jobs saved in USB flash drive, by scanning a pre-printed barcode, without the need to connect to a computer. This feature is especially helpful when many files are stored in USB flash drive. Offline working feature allows the same cutting job to be sent repeatedly, users can copy cutting jobs offline, which is much more convenient than connecting to a computer with a USB cable.

Reflective film, heat transfer film, paint protection film/PPF, vehicle film, window tint, vinyl sticker, heat transfer vinyl, magnet sticker, anti-blasting rubber, cell phone decorative film, multi-layer film, flexible circuit film, glass film, PVC and PET of certain thickness, 500 GSM cardboard.

Automatic flatbed die cutter is suitable for automotive aftermarket, car decoration, traffic sign industry, sign manufacturing, packaging, garment signature, shoe design, luggage design, laminating industry, offset printing, sample making, pop display, and every other industry you can think of that needs cutting.

VICUT specializes in flatbed cutting machines and label cutting machines, etc. If you are looking for a reliable machine supplier for your business, welcome to contact us.