vicutcnc@cncvicut.com

vicutcnc@cncvicut.com

+86 551 6577 4134

+86 551 6577 4134

Get A Quote

Get A Quote

vicutcnc@cncvicut.com

vicutcnc@cncvicut.com

+86 551 6577 4134

+86 551 6577 4134

Get A Quote

Get A Quote

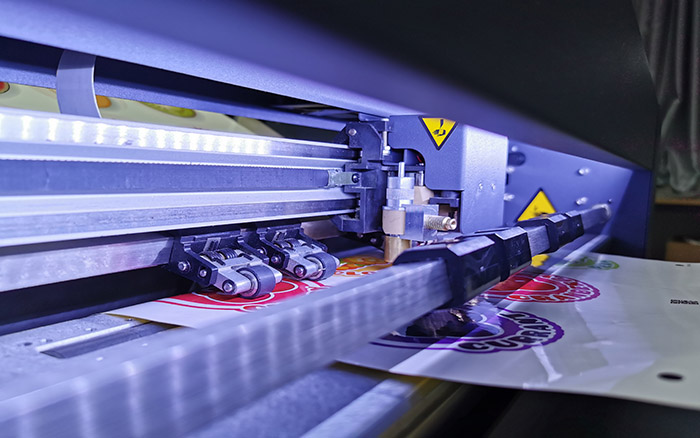

The Vulcan Automatic Sheet Fed Label Cutter SC-350 is ideal for reliable and automatic small batch label production and tag DIY business. The sheet label cutter can do continuous contour-cutting job on various printable self-adhesive stickers and labels, great choice of copy shops, graphic shops, office applications and many others.

● Automatic feeding system.

● Unattended operation.

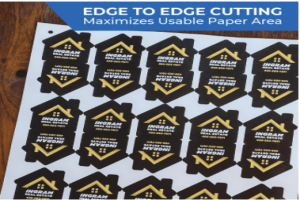

● Stickers can be printed edge to edge on the media, even outside the registration marks. This allows maximum paper area to be utilized, saving you money.

KEY FEATURES

STABLE AND FAST PAPER FEEDING

Fully automatic,advanced constant paper feeding system ensures continuous multi-sheets cutting without paper jams.Truly realize "unattended" operation.

SPEED IS PRODUCTIVITY

Paper feeding only 2 seconds, while marks detecting only 4 seconds, and maxi cutting speed is 1200mm/s. Greatly improve the working efficiency.

MULTIPLE DATA TRANSFER MODES

Vulcan SC-350 supports U-disk, USB cable and Network transfer cutting files. Users can choose appropriate working mode according to their needs.

ADVANCED DIGITAL CUTTING TECHNOLOGY

Combination of high resolution camera registration system and QR-code job retrieval, makes DIY label cutting much easier.

EASY OPERATION

Plug and play, no additional drivers needed.The 4.3 inch HD touch screen, sensitive response, makes the operation even more convenient and user-friendly.

EASY ACCESS MAINTENANCE

The side panels of SC-350 are easily load-off for easier maintenance .Three sensors inside for easy checking problems and maintenance.If any sensor fails, the corresponding feedback will appear on the display screen,no need to replace and check one by one.

FREE FIRMWARE UPGRADE

The factory continuously develops and optimizes the functions of the machine, and regularly updates the machines sold without cost.

Supports both Windows and Mac

Technical Parameters

| Model name | Automatic feeding label cutter SC-350 |

| Supported media size | Width:185 to 350mm.Length:150 to 800mm; A4,A3,SRA3,A3+ sheets and customized sheets |

| Scan device | High resolution CCD camera |

| Register mark type | dot mark |

| Job retrieval | QR code |

| Paper feeding time | 2 seconds(SRA3 sheet) |

| Marks detecting time | 4 seconds(SRA3 sheet) |

| Maximum cutting speed | 1200mm/s (high speed mode) |

| Data transfer | USB 2.0(full speed)/U-disk/Network |

| Software | SignCut Pro2 (supports Ai/coreldraw plugin) |

| Max.cutting force | 400g |

| Driving system | Servo |

| Command type | HP-GL |

| Working method | PC/U-DISK |

| Mechanical resolution | 0.01254mm |

| Cutting tool | cemented carbide blade |

| Cutting accuracy | 0.2mm (contour cutting) |

| Minimum character size | Approx. 5 mm square |

| Material thickness | Up to 350gsm |

| Capacity of exit tray | 200sheets (up to 40mm) |

| Operation panel | 4.3 inch touch LCD |

| Compatible OS | Windows and Mac system |

| Working voltage | 100 to 240 V AC, 50/60 Hz (Auto switching) |

| Power consumption | 60w |

| Operating environment | Temperature: 10 to 35 degree, Humidity: 35 to 75% RH (non-condensing) |

| External Dimensions(mm) (W × D × H) | Exit tray : 406 x 462 x 186 mm Exit tray+Cutter+Media support tray:1109 x 747 x 594 mm |

| N.W./G.W. | 33kg/36kg |

| Packing Size | 870 x 550 x 580 MM / 0.28CBM |

| Warranty | 2 years |

Details Description

User friendly touch screen

Easy toggle of arrow key speeds for carriage control: Fast (x10) / Slow (x1) Single Re-cut button to instantly repeat last job.

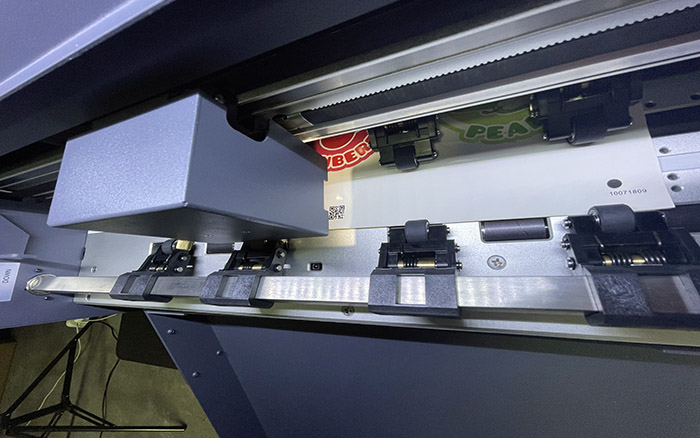

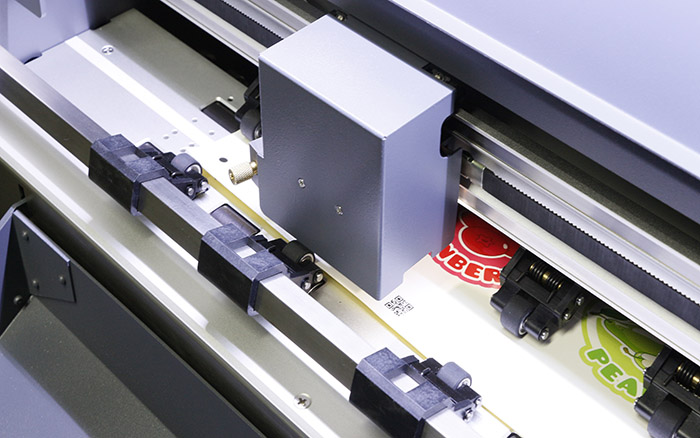

Stable carriage

Being one of the key moving parts, the carriage has to last. The SC-350 carriage uses only the highest quality materials,and is designed to handle extensive daily use. Vulcan engineers have solved the heat build-up problems that often plague other carriage designs.The camera in the carriage was carefully chosen to be fast and reliable. The camera can scan four registration marks within 3 seconds. Combined with the ability to feed in a sheet in under 3 seconds and read the QR code, you can cut more sheets per hour.

Camera System

The SC-350 uses a high resolution camera for accurate detection of registration marks (as small as 5 mm). The camera can even see reg marks on both colored and transparent materials. The ability to scan small reg marks saves material, thus reducing production costs. The ability to scan four reg marks within less than 3 seconds saves production time and reduces costs even further.

QR-code system

SC-350 reads QR-codes on the printed media, allowing automatic matching of print and cut files.This both speeds production and eliminates any chance of mismatched files.

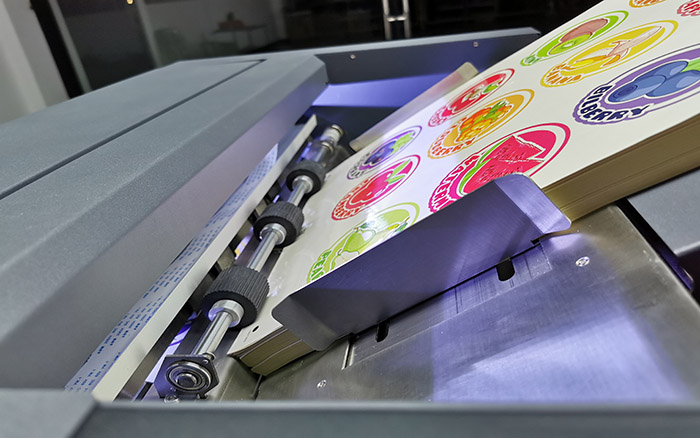

Automatic paper feeding system

The unique paper feeding structure can not only adapt to more material ranges, but also can install 300 sheets of A4 paper at a time. Suitable for multiple sheets size (A4,A3,A3+), also avoid paper shifting during working, guarantee better precision. Paper feeding time within 2 seconds.

Large capacity of exit tray

Movable exit paper tray with sheets adapter, suitable for containing different size paper. Easy to dismounting, large volume with 40mm depth, holding up to 200 sheets depends on the thickness of materials.

Led Working Light

Led lights provide stable lighting so that the camera can reliably read the QR codes and registration marks regardless of the external lighting conditions. This leads to improved reliability during unattended operation conditions.

U-Disk function

PLT-files saved on USB thumb drives (U-disk) can be used for direct output. This means that the SC-350 can be used without being connected to a computer.

Network interface

A. Stable communications over long distances.

B. Control one sheet cutting plotter from multiple computers.

C. Control different sheet cutting plotters from one computer.

SignCut Pro software

The stand-alone software SignCut Pro2 is very powerful to support Vulcan SC-350 sheet cutter. The designers use coreldraw or illustrator to create the registration marks with help of plugin which offered by SignCut, and then transfer the cutting files to the cutter via SignCut Pro software, thus, the files will not be distorted. Signcut also provides professional design software “Signcut draw” for free, so that users can design complex graphics freely.

Tools & Accessories

Calibration tool

Used for setting up and calibrate cutter before machine working.

Blade holder

This precision engineered components sits in the dual tool head and holds the cutting blade of choice. The tool is adjustable manually to obtain the desired length of blade-tip. Keep an extra blade holder handy to minimize blade adjustment when working with different materials.

Cutting blade 30 degree

Replacement 30° angle good for cutting thicker, more dense material. 5 Pack of Durable Replacement Blades. Fine sharpened tip excellent for detail work.

Cutting strip

Replace your cutting strip every 6 months to a year depending on your usage. Gouges or adhesive residue on the strip can accumulate over time and usage and cause tracking errors on your cut job.New strips fix many common cut issues.

Application

Material: Various printable self-adhesive materials can be used. Such as, Photo Paper, T-shirt Transfer Paper, Photo Quality Inkjet Card, Stickers, Glossy paper, Transparent Films, etc.

Field: Automatic sheet cutting machine SC-350 is the ideal machine for reliable and automatic production of contour-cut stickers and labels in the business areas of copy shops, product labeling, office applications and many others.

Working Samples:

|  |  |  |

|  |  |  |

|  |  |  |

Company Service

As a professional digital label die cutter supplier, Vicut believe good product quality and service always get loyal clients, CE, SGS and BV certified cutting machines, 24/7 online service, all-round technical support & solutions offered within 8 hours. Remote training, available user manual and operation video are provided.

Packing photos

|  |  |